Refinery blog

Search by topic

Search by application

Reducing scope emissions at refineries: A closer look into utilizing energy efficiency profitably

An essential first step when utilizing energy efficiency as a tool towards reducing carbon footprint and increasing profit is identifying the right energy efficiency opportunities that make the best economic sense.

Enabling sustainability goals of renewable fuels projects

Renewable fuels processes unleash an energy source that can be used to reduce carbon intensity, but most customers don’t take advantage of it. Find out how Alfa Laval supports projects to take “free” energy to create sustainable solutions.

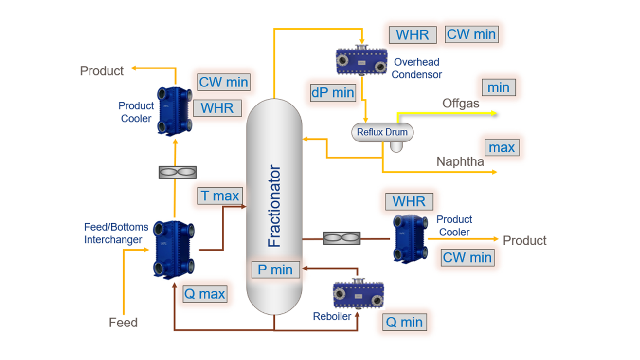

Energy efficiency opportunities around different heat exchanger positions in a fractionator – Part 1

Identifying areas of improvement when reducing carbon footprint and making a profit via the opportunistic approach is accomplished by evaluating areas where you already plan to spend money. Read our first blog on the four main areas of focus when utilizing an opportunistic approach to energy efficiency.

Efficient wastewater cooling and reuse

Environmental regulations and freshwater availability are making it difficult for refiners to maintain and expand production capacity. Learn how Alfa Laval can provide sustainable wastewater solutions for your refinery.

Using Packinox heat exchanger for catalytic reforming

This blog illustrates how welded plate heat exchangers compare with traditional technologies in the catalytic reforming process.

Benefits of Compabloc technology versus shell & tube

Our experts explore the benefits of using welded plate bloc type heat exchanger technology like Compabloc versus using shell and tubes in your refinery.

Reducing energy consumption in industrial refrigerant systems

Optimizing large industrial refrigeration processes is possible through the application of various Alfa Laval Heat Exchanger technologies.

Refinery alternatives to box coolers

See why oil refineries are making the switch from antiquated box coolers to heat exchangers.

Debottleneck naphtha hydrotreaters with highest project ROI

Discover how to use capital and energy efficient Compabloc technology in naphtha hydrotreating.

Overcome the challenges of cooling desalter water effluent

Read how Alfa Laval’s spiral plate heat exchanger technology solves the challenges in cooling desalter water effluent.

Reduce carbon intensity while improving bottom line in the refining sector

Learn how Alfa Laval has partnered with refineries to reduce their carbon intensity and achieve sustainability goals.

How to cut your refinery cooling water consumption by 30-50%

Water is one of the key utilities necessary to process a crude oil into a refined product. One way to economically reduce your cooling water requirement is to design your exchanger with temperature cross with the help of compact welded plate heat exchanger technology.