With so many different types and styles of tank cleaners available, selecting the right one for your process can seem overwhelming. The more you can identify what needs to be cleaned and why, the more clearly you will be able to analyze the methods used to clean and exactly which equipment should be used.

With the right tank cleaning device, you can save up to 70% in time, water and chemicals needed per cleaning cycle. That savings goes directly to your bottom line and can increase your plant’s productivity.

If you’re looking to change, upgrade, or optimize your CIP process, first consider these five questions to evaluate what device will be needed. Bonus points if you have a drawing of your tank. With a tank drawing, these questions can be answered quickly!

1. What are the dimensions of your tank?

The size of the tank will determine the size of the device needed to clean. For example, a device that is correctly sized to clean a 5’ diameter tank would not be appropriate for a tank that is 25’ in diameter because the effective range of the cleaning jets and the CIP fluids in the smaller unit would be too short to reach the walls of the large tank.

2. What is the nature of the residue?

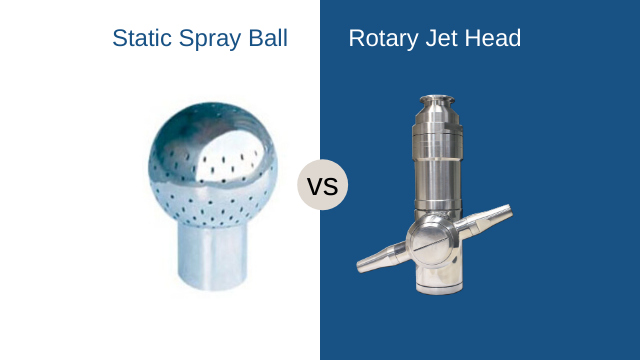

What are you trying to clean and what is the consistency? It could be anything from yogurt to paint, toothpaste to flour and everything in between. The nature of the residue will help determine what type of device will most efficiently clean the tank in the shortest time and using the least water and CIP chemicals. For example, a tank with dried or baked on residue may require a Rotary Jet Head with high impact for optimized cleaning whereas a tank with a lite, water soluble residue could be efficiently cleaned using a Rotary Spray Head.

3.What are the available openings on the tank?

If the tank cleaning device needs to be installed through a specific sized opening in the tank, the device you choose needs to be able to fit. This is a consideration for the initial installation and removal for maintenance. Additionally, if the device is portable (installed before cleaning and removed after cleaning) the size of the device must be able fit in and out of the opening.

Don’t forget the size of the drain. Cleaning fluids must adequately drain without pooling to allow the device to clean the bottom of the tank as well.

4. Does the tank have any obstructions?

Obstructions could be any number of objects in the tank such as heating coils, agitators and scrapers. These obstructions can result in “shadow areas” and impede the coverage of the CIP solution. For the most effective clean, your tanks may require multiple or specialty devices to clean properly.

5. What is the pressure and flow available from your CIP system?

You’ll need to know the pressures and flows at the tank, not just at the pump. The CIP supply pumps must be capable of delivering the proper flow and pressure to the tank cleaning device. Different tank cleaning devices will also require different flows and pressures.

Devices such as Rotary Spray Heads use elevated flows and operate at lower pressures, making them an excellent replacement for inefficient sprayballs while providing up to 30% savings in operating costs. Rotary Jet Heads are high pressure and low flow that result in high-impact cleaning and save about 70% in operating costs.

With answers to these five questions, you're well on your way to ensuring that you select the most effective tank cleaning machine. To help you keep track, download this simple checklist to record the details of your tanks and the residue being cleaned.