The tank cleaner you use affects your plant’s efficiency, uptime, and ultimately your bottom line. Keep reading to discover everything you need to know about why the type of tank cleaner you use matters.

Some tank cleaners are more efficient than others

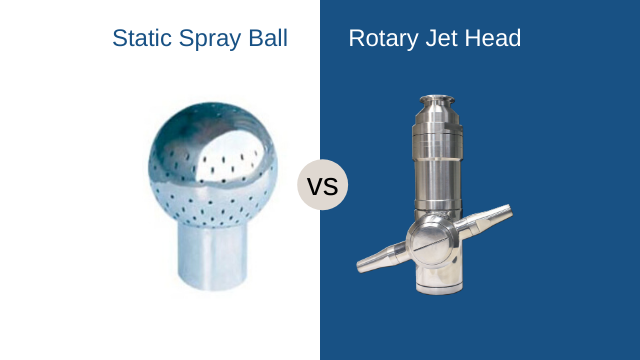

There are several types of tank cleaners on the market today. They usually fall into one of three categories: Static Spray Balls, Rotary Spray Heads, and Rotary Impingement (Rotary Jet) devices.

Static Spray balls have numerous holes through which the wash fluid is released. They rely on the sheer volume of wash fluid and the cascading effect it creates to clean the entire tank surface. The flow rate of a spray ball is divided by the number of drilled holes, which means the more holes there are, the lower the flow rate.

While adequate for easy to clean applications, Static Spray Balls are less efficient than other, more advanced tank cleaning technologies. This is due to the lack of movement, which results in the cleaning solutions only hitting specific impact points where the liquid stream directly hits the tank wall. You can only hope that gravity will develop a falling film that results in the other areas getting clean.

Rotary Spray Heads, on the other hand, have a rotating head that creates a flat fan spray to evenly apply the water and chemicals to the entire surface of the tank while increasing the mechanical action. An improvement over the spot cleaning of the spray ball, the even coverage of water and chemicals, along with a medium impact, creates a fully developed falling film to clean the tank. This leads to much higher efficiency because less water and chemicals are required for cleaning. Cleaning time is also reduced significantly.

Not every tank cleaner will meet your process needs

Different tank cleaners are built for different needs. Are you working with a dairy application that requires 3-A certification or a high purity application that requires full documentation and traceability? Or perhaps you work in the truck wash industry that needs more heavy-duty devices?

Many factors such as the dimensions of your tank, the nature of the residue, and whether the tank has any obstructions should be considered to choose the most efficient equipment. Getting this right will help you optimize your tank cleaning process and ensure that you’re choosing the most efficient equipment to get the results you need.

The more efficient you tank cleaner, the fewer resources required for operation

For tank cleaning, efficiency incorporates CIP, water, heating, disposal, and treatment needed to clean your tanks. With the right device, the amount of resources you use can drop by more than 30%. One of Alfa Laval’s Brewery customers saved 3.2 million gallons of water per year by switching to a new tank cleaning device. Imagine what your operation could do with this amount of energy and cost savings!

Rotary spray heads require significantly fewer resources than static spray balls because there is less energy needed to heat the water and pump the water, and less money needed to dispose of the water.

With fewer required resources, your tank cleaner will be more cost effective

A faster, more efficient clean ultimately leads to a reduction in cleaning costs and increases your bottom line.

Higher efficiency devices also save one of your most important resources: Time. With a 30% faster clean, a 90-minute cleaning cycle drops closer to 60 minutes. Now you’ve gained 30 minutes of production time just by changing your tank cleaner!

It’s important to consider your tank’s unique process needs when choosing a tank cleaning device. You may find that switching to a rotary spray head is exactly what you need to be one step closer to increased efficiency and resource optimization. Alfa Laval offers a drop-in replacement for your old spray ball with no need for infrastructure upgrades.

For help selecting the right device for your needs, chat with our team.