Ribbon blenders are widely used for effective mixing of a variety of substances that vary from dry powders, very viscous pastes, creams to meat and almost everything in between. Most ribbon blenders are a u-shaped trough with one or multiple helical agitators or “ribbons” that blend, fold, and agitate products using both an axial and radial motion. There can be variations on this design where the agitator could utilize paddles or plows for mixing. Regardless of the agitator type, these devices are very difficult to clean due to the multiple surfaces, shadow areas, and close tolerances.

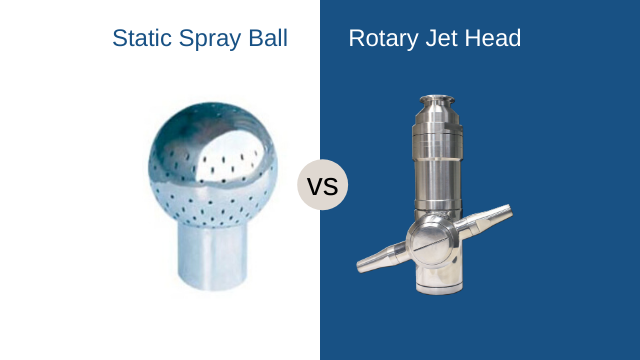

Because of the wide range of applications, there are several considerations to make when developing an effective sanitation process. In conjunction with your CIP system and using either an Impingement or Rotary Jet Head cleaning device (for difficult to clean residues) or Rotary Spray Head (for simpler residues), CIP cleaning of your ribbon blender can be accomplished efficiently, thoroughly, and in a much shorter time than inefficient fill and drain process or the time consuming hand cleaning.

Choosing the correct cleaning technology for your application involves a number of considerations:

Available CIP infrastructure

Rotary jet heads have different pressure and flow requirements than manual hoses, static spray balls, or rotary spray heads and often require a CIP pump that can deliver higher pressure to the units. Although retrofitting a tank may involve some up-front costs, these are key investments in the long-term cleanliness of the ribbon blender. As with the rotary jet heads themselves, setting the equipment up to clean effectively allows for up to 70% faster cleaning cycles, more savings on water and ribchemicals, and less downtime due to cleaning.

Residue type

Consistent, repeatable cleaning allows for repeatable, reliable batch quality at increased production volumes. As with any tank, many of the decisions about cleaning can be made based upon how difficult the contents of the tank are to clean.

Types of tank soil can be generally grouped into three categories based on how hard they are to remove:

1.Thin, non-sticky liquids that are water-soluble and light, dry powders that are easy to rinse off

2.Soil that is dried or caked on, any gels and lotions, and any films or residues that are slightly sticky, crusty, oily, or slimy

3.Viscous, tar- or sludge-like, and anything that has been burnt or severely caked onto surfaces inside the tank, often the hardest-to-clean debris

Although easier-to-clean residues can sometimes be managed with light rinsing, oftentimes a tank needs more cleaning power to consistently remove debris from all of the internal nooks and crannies. Designed to operate at lower flows and higher pressures than static spray balls or rotary spray heads, rotary jet heads are capable of carving away soils in a fraction of the time of their lower-pressure counterparts. Depending on the rest of the tank setup, one or more rotary jet heads may be needed for an effective cleaning cycle.

Ribbon/Agitator size and complexity

Tank agitators come in a wide variety of shapes and sizes. For ribbon blenders in particular, the agitators often have several twists and turns and a significant amount of surface area. There are two key aspects of ribbon agitators to consider for cleaning: the diameter of the central agitator shaft (if there is one), and the size and shape of the agitator blades.

Any in-tank equipment, such as the agitator, acts as an obstruction to the cleaning device(s). This creates “shadow areas” that then require multiple cleaning heads to reach around. The larger the obstruction, the more shadow areas will need to be accounted for in order to maintain cleanability. This applies to both the central agitator shaft and to any blades and/or paddles on the agitator.

As such, an agitator shaft [larger than 1 inch in diameter] may require at least two cleaning heads, positioned staggered across the tank’s centerline, in order to reach the shadow area(s) on the floor of the blender tank. Similarly, large angled paddles or ribbons with lots of twists and turns may require two or more units to reach all of the surface area from different directions.

Ribbon blender size and shape

The final consideration to make when upgrading the CIP procedure for a ribbon blender is the tank itself. The size and general shape of the blender dictates the difficulty of cleaning and, therefore, how many cleaning devices will be needed to properly clean it.

Whether or not the blender has a lid may also affect the way in which it can be cleaned. Several rotary spray heads and a few rotary jet heads come in directional, downward-cleaning configurations to prevent up-spray out of the open-top models.

To automate your Ribbon Blender cleaning for faster, more efficient results, contact Alfa Laval.