Sulphur recovery processes

In this refinery application series on Sulphur recovery processes (Amine treatment & sour water stripping); explore how Alfa Laval's welded heat exchanger technologies have been applied to debottleneck, increase capacity, reduce CAPEX, increase energy efficiency & reduce utilities.

Case stories

An oil refinery in the USA increased capacity and heat recovery in an absorber-stripper system by exchanging a set of shell-and-tube heat exchangers for two Alfa Laval Compabloc compact heat exchangers

Rosneft have minimized Project CAPEX by using Alfa Laval Compabloc as Condenser & Reboiler in Gas Sweeting Process

Located outside Gela in southern part of Sicily, the Gela facility is one of the leading refinery in the Mediterranean area. Learn how Alfa Laval's Compabloc technology has helped Gela improve its performance while reducing emissions

Article

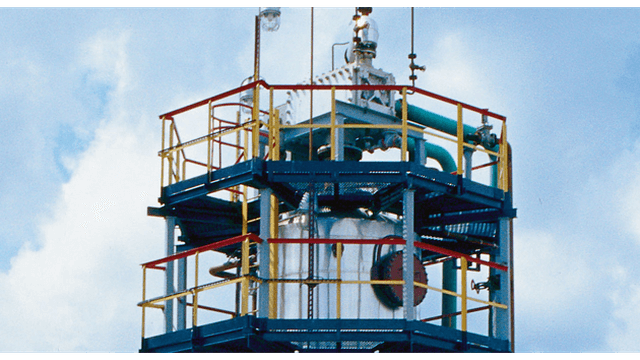

A reboiler for the space age? This article describes an innovative reboiler solution, comparing installation costs and space constraints.

Read other relevant refinery blog posts

Debottleneck naphtha hydrotreaters with highest project ROI

Overcome the challenges of cooling desalter water effluent

How to cut your refinery cooling water consumption by 30-50%

Refinery alternatives to box coolers

Reduce carbon intensity while improving bottom line in the refining sector

Reducing energy consumption in industrial refrigerant systems

Benefits of Compabloc technology versus shell & tube