Craft brewing

Add our expertise and professional brewing equipment to your energy for craft brewing. Alfa Laval can help you on your unique craft brewing journey and overcome challenges. It may be the need for quality consistency, growing production target , or whether you could, actually, be doing something better? Finally, getting new equipment installed right the first time around. We have the right craft brewing equipment as well as the experience, knowledge, and shared passion to help you.

Amazing, stand-out beers

- Solutions for all brewers, by those who know their trade

- Proven track record of improved yield and reduced water and energy consumption

- Flexibility to enable you to quickly tap into new trends in craft brewing

- A global service network of craft brewing specialists to support you with brewing equipment, systems and expertise

Our proven craft brewing equipment and solutions, from individual components and process modules to turn-key projects, are designed and manufactured for independent local craft beer producers and global craft breweries to improve beer quality, optimize production and reduce costs and environmental impacts. By enabling tight control over your brewing and your costs, we can help you make amazing, stand-out beers.

Looking for brewery solutions?

Elevate your brewing process with Alfa Laval's innovative beer brewing equipment and brewery technology. Learn more about our brewing solutions and available products or speak with an expert.

Better quality through innovation

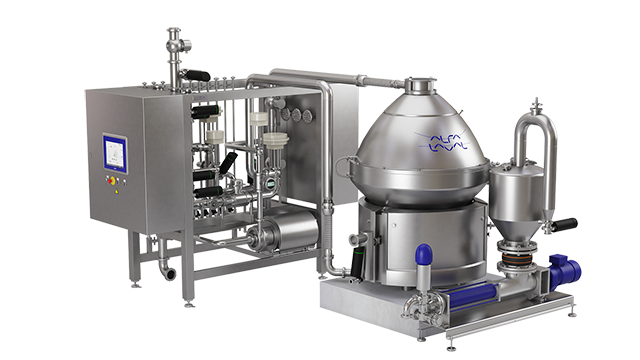

Learn how centrifuges can help craft breweries reduce energy consumption and improve yields

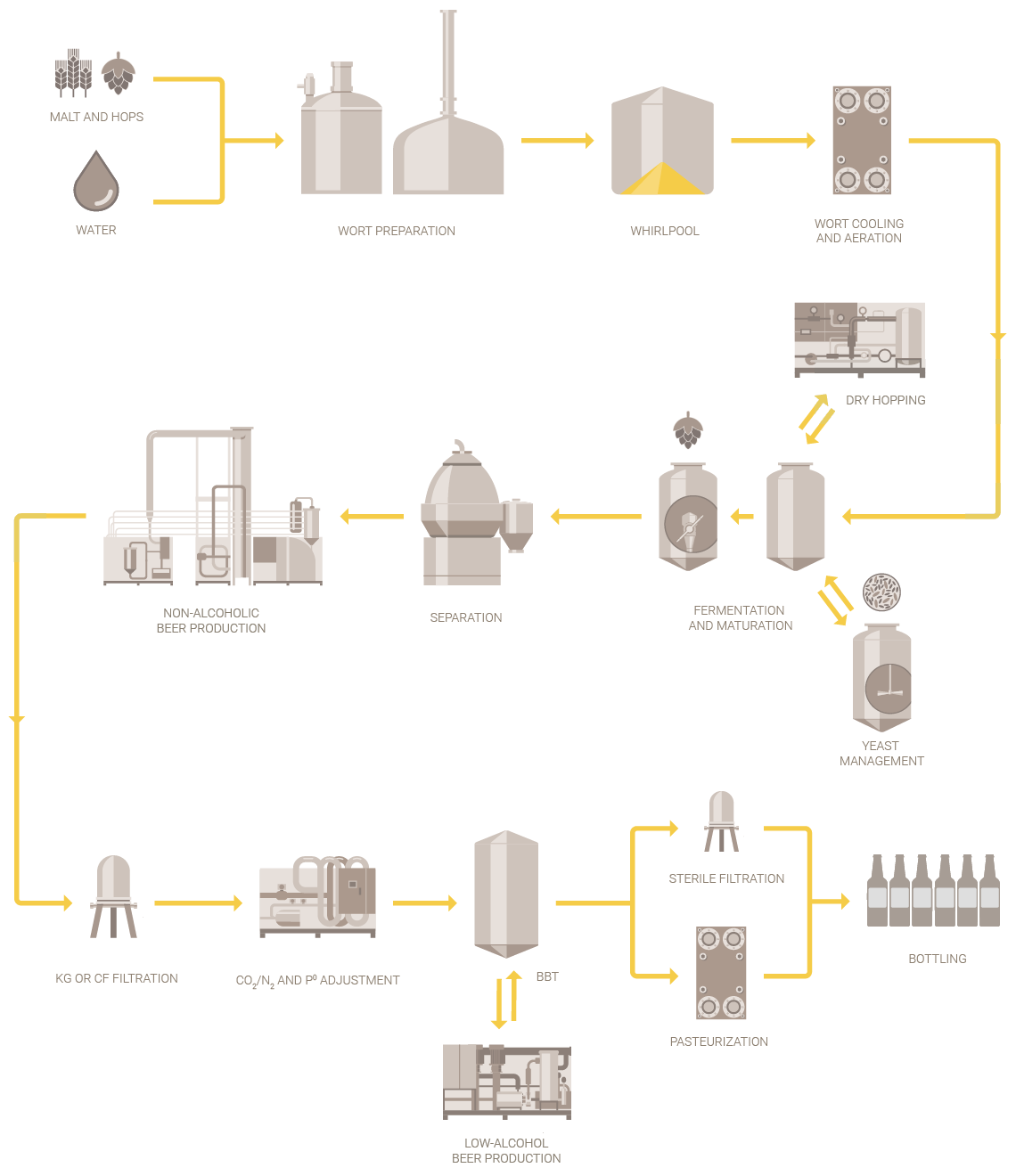

Craft brewing process

Eliminate the challenges in the brewing process with our brewing equipment

Improving operations is an everyday fact of life for brewers, all the way from the brewhouse to packaging. Incremental improvements to wort yields, beer loss or water usage can amount to significant savings over the long term. See how our brewing process expertise, solutions and individual components for each process block help avoid and overcome common issues in the brewing process.

Brewhouse

Recover wort, reduce waste, save energy and improve brewhouse efficiency and hygiene.

Coldblock

Recover beer, shorten fermentation and maturation time, improve yeast management, sampling and more.

Filtering & treatment

Avoid spoilage, improve beer quality and diversify your products.

Preparation of lines & cleaning

Optimize cleaning and preparation of lines.

Utilities

Optimize cleaning sequences, reducing overall energy and chemical usage.

Highlighted technologies

Happy brewers

Boston Beer Company

One of the first things we installed was an Alfa Laval Brew separator. Alfa Laval was also willing to take on much of the project management. They successfully managed the full process and were there for us throughout with technical support.

David Grinnell, Vice President of Brewery Operations, The Boston Beer Company, USA

Harpoon Brewery

The Iso-Mix system provides us with a fast, consistent way of adjusting CO2 content and gravity as well as making other additions that ensure less manual labour and reduced risk of delays in our packaging operations.

Al Marzi, Vice President and Chief Brewing Officer, Harpoon Brewery, USA

Amager Bryghus

With just one compact Brew 80 unit, you can allow yourself to be more creative. Now it’s only your imagination that is the limiting factor in terms of experimenting with flavours. This equipment has proved to be more versatile than we had imagined, and it gives a great boost to our creative, unconventional approach to brewing, and products that really get noticed in a crowded market.

Morten Valentin Lundsbak, Founder, Amager Bryghus, Copenhagen, Denmark

Rebellion Beer Company

I believe that craft brewing on a relatively small scale as we do, is still a traditional art creating distinctive characterful beers using the time-honoured brewing methods but coupled with elements of modern technology, such as the Brew 80.

Co-owner Mark Gloyens, Rebellion Beer Company Ltd. Marlow, Buckinghamshire, UK

According to Art Oestrike, president at Jackie O's, "Barrel ageing beers is a fickle business. You take this big, beautiful imperial stout or barley wine and throw it into a freshly dumped bourbon barrel and let it sit in our warehouse. A year and a half after packaging it, they start to turn sour. They don't taste good."

Watch the video to hear how Flexitherm Mini 'flipped the barrel aging programme on its head'.

When quality comes first

Discover well-designed, trusted brewery equipment in the "Solutions for craft brewers" brochure and see what Alfa Laval can do to meet your needs.

How a centrifuge fits your brewery

Click play to watch our Craft Beer Professionals webinar recording and get:

- An inside view of how a centrifuge works

- Knowledge of the surprising number of applications

- Service tips: From CIP to maintenance

Let us help

Submit the form and one of our craft brewing experts will reach out.