Increase sludge dryness by 2% or more and slash sludge management costs with an Orege SLG system

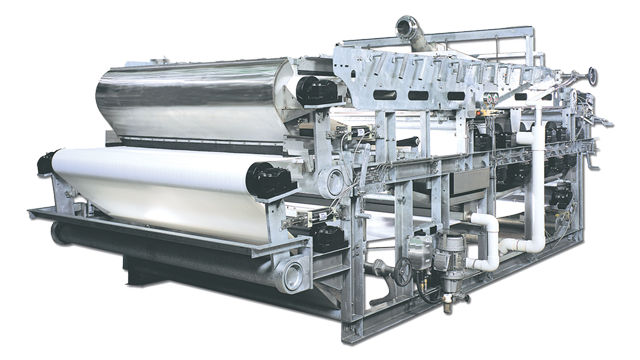

Pre-treating sludge with an Orege SLG system immediately before processing it through the Alfa Laval AS-H belt filter press or gravity belt thickener can improve final sludge dryness by 2% or more (depending on process conditions). This can significantly reduce sludge management costs, frequently a major expense for a wastewater treatment plant. When you add up polymer, hauling, and operating expenses of managing sludge, costs can equal more than 50% of a plant’s budget. Reducing volume of sludge required to haul away can have big impacts on your bottom line.

Alfa Laval and Orege partner to improve sludge dewatering performance

Orege is an international cleantech firm that has delivered award winning proprietary technologies and solutions for the conditioning, treatment and reuse of sludge for over ten years. With bases in France, the US, the UK and Germany, Orege, an Eren Group subsidiary, supports its clients in a dozen countries around the world.

In June 2020, Alfa Laval and Orege signed a partnership agreement allowing Alfa Laval to become the only belt press OEM (Original Equipment Manufacturer) to offer the Orege SLG sludge conditioning system with greenfield and brownfield projects, in addition to belt filter press and gravity belt thickener rebuilds managed by Alfa Laval.

Reduce your sludge management expenses by:

- Increasing final cake dryness and reducing hauling volumes

- Reducing polymer use

- Increasing belt filter press / gravity belt thickener throughput

- All in a footprint of approximately 3’ x 5’

How can the Orege SLGTM solution improve your process?

The Orege SLG (solid, liquid, gas) solution can bring numerous benefits to your wastewater sludge thickening or dewatering process. Unlike other pre-treatment solutions, the SLG disrupts the rheology and structures within the sludge, and the separation of sludge solids from filtrate can be greatly enhanced and accelerated (illustrated below). This improves dewatering efficacy and reduces associated costs.

Benefits for your dewatering/thickening process:

- Target 2% or greater increased sludge dryness

- Reduced polymer use

- Increased throughput

Benefits for your entire wastewater treatment plant:

- Higher dewatering and thickening capture rates—producing a cleaner filtrate return with increased ORP

- Lower sludge viscosity—enhancing mixing and overall anaerobic digester performance

- Eliminate the need for substantial plant upgrades

- Reduced energy usage and lower carbon footprint

- Odor and corrosive gas reduction—stripping sludge of harmful gases

Ultimately, the Orege SLG can save your plant significant costs related to thickening or dewatering sludge. The target payback period for an Orege solution is 2-5 years, so over the life of the facility can save you hundreds of thousands of dollars in expenditures!

How it works

By working ahead of your thickening or dewatering equipment, the Orege SLG uses proprietary equipment and methods to alter the properties of your sludge with a primary impact of allowing it to shed water more easily, leading to increased dryness or the ability to increase throughput on the equipment.

Orege SLG uses compressed air and proprietary technology to change the actual rheology of your wastewater sludge, breaking down aggregate colonies and releasing bound water. The reaction process entrains air in the sludge and facilitates rapid and effective separation prior to dewatering.

Case story

Trust Alfa Laval and Orege to maximize your process effectiveness

Contacting a regional Alfa Laval sludge treatment expert is a great next step to learn about the Orege SLG solution and how it can enhance your Alfa Laval belt filter press or gravity belt thickener. They will work with your local sales representative as your partners with a goal of determining the best solution for your process.

Working will Alfa Laval and Orege will involve:

- Applying Alfa Laval and Orege engineering experience and application expertise to review your process and recommend the best technology solutions

- Discussing if lab and pilot testing can help ensure the right equipment is selected for your specific process

- Utilizing a global network of experts to work with you from idea through startup, and continuing with service of your thickening and dewatering equipment

How can we help?

With industry-leading wastewater technology and expertise based on the experience of thousands of installations, we can help analyze your unique situation and select the optimal equipment model, configuration, and services for your needs and budget. Get in touch by submitting a general inquiry using the contact form below.