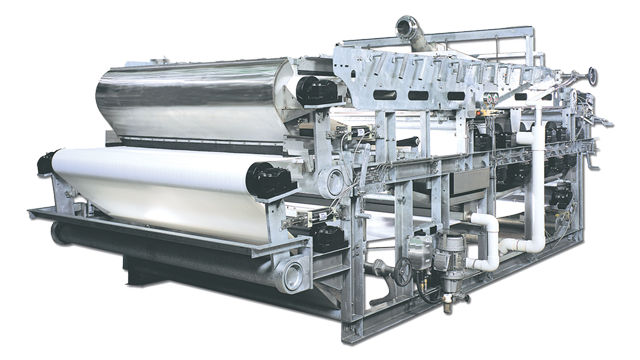

AS-H Belt Press G3

The Alfa Laval AS-H G3 belt filter press dewaters high volume throughputs of low solids feed into high solids dry cake. It is available in a number of configurations that can be customized to your wastewater dewatering needs.

The industry standard for performance in wastewater dewatering

- Flexible design – easily upgraded and reconfigured as your needs change

- High precision variable-orifice polymer mixer

- High volume, high cake solids performance

- Low maintenance, operator friendly design features

- 3-belt, independent gravity deck design available for low solids (< 1.5% solids)

A flexible design, because you can’t always predict the future

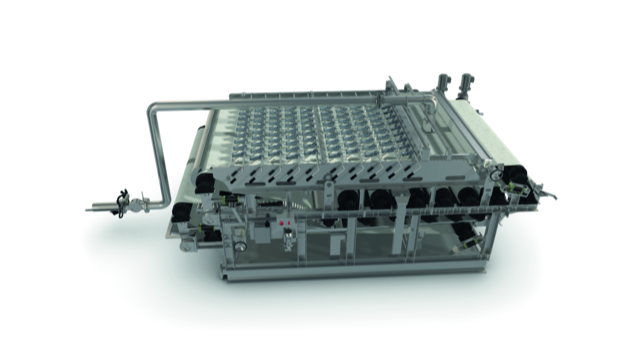

A key strength of the Alfa Laval AS-H G3 belt filter press is the modular design. It can be configured into several different designs depending on your sludge / residual dewatering needs.

Whether you have dilute sludge and require the pre-thickening 3-belt design, or want the extra dewatering achieved by expanding to the 12-roller layout, the Alfa Laval G3 belt filter press can be modified to accommodate your process specifications.

Modifications can easily be made in the future as well if conditions change thanks to the modular nature of the machine.

How it works

The Alfa Laval AS-H Belt Press G3 begins the dewatering process with a proprietary variable-orifice, in-line polymer mixer that combines polymer and slurry instantly, in less than one second. The product then begins to drain over an endless, horizontal porous filter belt. The product is then sandwiched by a second filter belt before further dewatering by a series of decreasing diameter rollers. Final moisture removal is achieved by shear rollers arranged to give minimum 180 degree belt wrap in order to optimize dewatering.

Operator-specified belt tensioning is automatically maintained by a hydraulic belt tensioning and alignment system, which recognizes and corrects for subtle condition variations such as belt stretching or process changes. The arrangement of the Belt Press G3 gravity drainage zone ensures even distribution of the conditioned slurry over the effective width of the moving filter belt.

The Belt Press G3 is equipped with lifetime-rated bearings, each protected from contaminates with triple-labyrinth seals and shaft-mounted splash guards.

Meeting your exact requirements

A variety of features and options makes the high-capacity Alfa Laval AS-H G3 belt filter press an excellent choice for your dewatering needs:

- Available in 8 or 12 pressure roller designs

- Extended deck and 3rd belt independent pressure deck options allow for excellent dewatering performance under a variety of conditions

- Adjustable wedge dewatering zone allows for process optimization

- Lifetime rated bearings

- Radial grid and perforated roller to accelerate dewatering

You may also be interested in:

Lab and pilot testing for municipal and industrial water and wastewater

Alfa Laval has a full testing lab to determine the best solution for achieving the sludge thickening and dewatering results you need. Pilot testing also available.

Solutions for the Circular Economy

More and more wastewater treatment plants are discovering the benefits of a circular, holistic approach to wastewater treatment. Cost savings, reduced environmental impact and new income streams from recovered resources are but a few. Every wastewater treatment plant is unique and has its own set of challenges and opportunities. With our expertise in processing and our broad range of products, we can support your shift to a circular resource flow. Regardless of whether you are a contractor, designer or plant operator we can help you find the optimum solution for your specific project.

10 top tips to keep your AS-H Belt Filter Press performing optimally

Have an Alfa Laval AS-H Belt press? Here are some top tips to help ensure that your equipment continues to perform at peak dewatering performance.

How can we help?

With industry-leading wastewater technology and expertise based on the experience of thousands of installations, we can help analyze your unique situation and select the optimal equipment model, configuration, and services for your needs and budget. Get in touch by submitting a general inquiry using the contact form below.