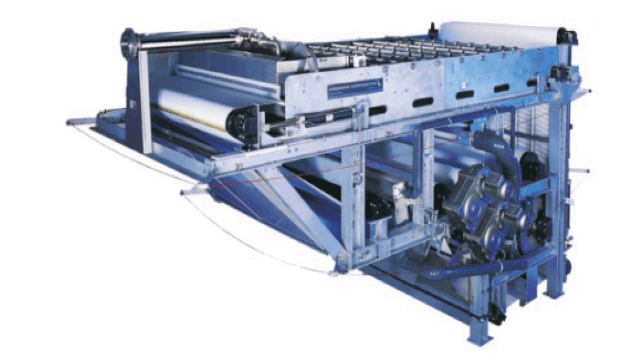

AS-H Winklepress

The Alfa Laval AS-H Winklepress is a high performance belt filter press used for dewatering in municipal and industrial wastewater applications. The units use specialized processing zones to achieve consistent cake dryness at high throughput volumes with low energy and polymer requirements.

Exceptional dewatering performance for maximum cake dryness

- Ideal for applications where the highest dry solids are required

- Low polymer requirement, so costs are reduced

- Long service life design with lifetime rated bearings

- Easy to upgrade in the field with additional pressure zone rollers

- Extended pressure profile – ideal for gentle treatment of nutrient rich sludges

How it works

The Alfa Laval AS-H Winklepress belt filter press begins the dewatering process with a variable-orifice, in-line polymer mixer that combines polymer and slurry instantly to facilitate rapid flocculation. The product then begins to drain over an endless, horizontal porous filter belt. The product is then sandwiched by a second filter belt in a unique vertical wedge zone (allowing for improved drainage), before further dewatering by a series of decreasing diameter rollers. An optional high solids pressure zone can be employed when maximum cake dryness is desired, resulting in a 10-20% dryer cake.

A fully live belt alignment and tensioning system is employed, that is pre-piped and pre-wired, eliminating any need for civil work or additional lines. The design and drain pan configurations simplify cleanup and allow access to key areas of the machine.

The Winklepress is equipped with lifetime-rated bearings, each protected from contaminates with triple-labyrinth seals and shaft-mounted splash guards.

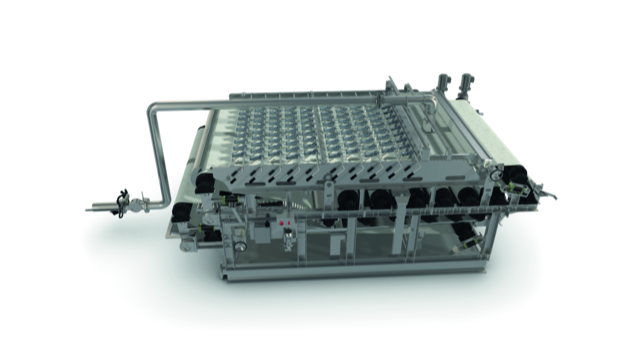

Available in two models and configurable to your needs

The AS-H Winklepress comes in two models, both produce exceptionally high dry solids cake. It’s robust design allows for high operating pressure and extended life for components. It comes in both an open and fully closed design. The enclosed design reduces odor emissions – allowing for a smaller odor control system and an improved environment for your operators.

Winklepress

Winklepress Enclosed

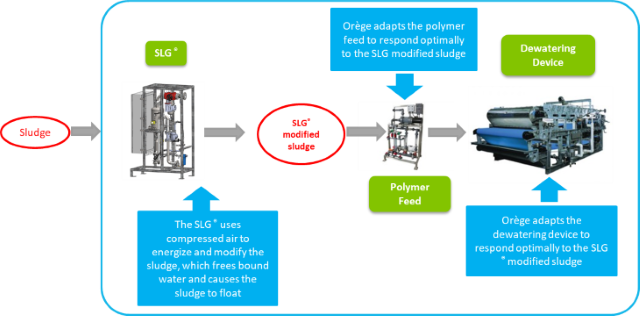

Achieve 2% or more additional dry solids from your belt filter press or gravity belt thickener

When placed ahead of an existing belt filter press or gravity belt thickener, the Orege SLGTM sludge pre-treatment system changes the rheology of your sludge so that it releases water more freely. Its small footprint means it can likely fit in your existing facility. Alfa Laval has an exclusive agreement to supply Orege in greenfield and brownfield applications.

Reduce your sludge management expenses by:

- Increasing final cake dryness by 2% or more and reducing hauling volumes

- Reducing polymer use

- Increasing belt filter press / gravity belt thickener throughput

Learn more about the Orege SLGTM system

You may also be interested in:

10 top tips to keep your AS-H Belt Filter Press performing optimally

Have an Alfa Laval AS-H Belt press? Here are some top tips to help ensure that your equipment continues to perform at peak dewatering performance.

Lab and pilot testing for municipal and industrial water and wastewater

Alfa Laval has a full testing lab to determine the best solution for achieving the sludge thickening and dewatering results you need. Pilot testing also available.

Solutions for the Circular Economy

More and more wastewater treatment plants are discovering the benefits of a circular, holistic approach to wastewater treatment. Cost savings, reduced environmental impact and new income streams from recovered resources are but a few. Every wastewater treatment plant is unique and has its own set of challenges and opportunities. With our expertise in processing and our broad range of products, we can support your shift to a circular resource flow. Regardless of whether you are a contractor, designer or plant operator we can help you find the optimum solution for your specific project.

How can we help?

With industry-leading wastewater technology and expertise based on the experience of thousands of installations, we can help analyze your unique situation and select the optimal equipment model, configuration, and services for your needs and budget. Get in touch by submitting a general inquiry using the contact form below.

Request a quote