Finding the right gasketed plate heat exchanger for your application doesn't have to be difficult. The main differences are explained below.

If you prefer to speak to an experienced plate heat exchanger engineer, we're ready to assist with your selection based on your specifications.

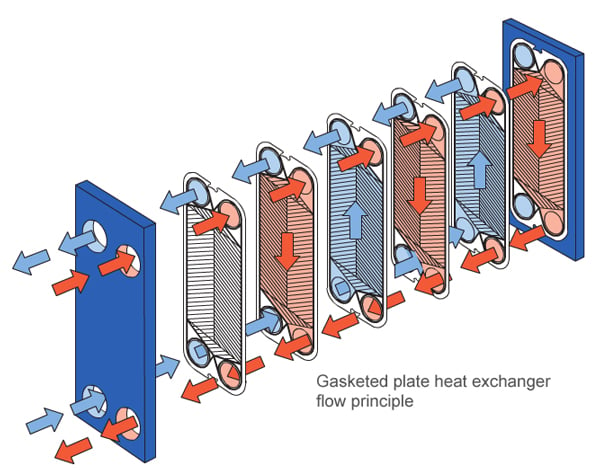

Industrial gasketed plate heat exchanger's versatility allows it to be designed and configured for applications ranging from relatively simple duties with low requirements to very demanding duties with the highest requirements on both performance and documentation. The models are used for heating, cooling, heat recovery, condensation, and evaporation. However, if you're working with an HVAC application, you'll likely want to choose an AHRI certified plate heat exchanger.

Learn more about Industrial gasketed plate heat exchangers

The AlfaQ range is similar to the Industrial range, except they're certified according to the AHRI Liquid to Liquid Heat Exchangers (LLHE) Certification Program which ensures thermal performance according to manufacturers’ published specifications in the HVAC market.

The AlfaQ range is similar to the Industrial range, except they're certified according to the AHRI Liquid to Liquid Heat Exchangers (LLHE) Certification Program which ensures thermal performance according to manufacturers’ published specifications in the HVAC market.

Learn more about AlfaQ AHRI certified plate heat exchangers

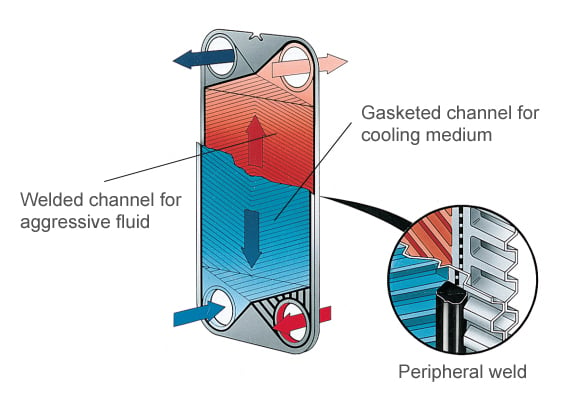

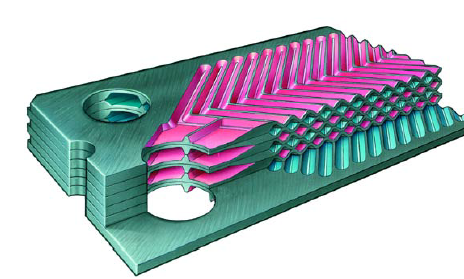

Use Semi-welded gasketed plate heat exchangers as evaporators and condensers for refrigerations systems, when gaskets are not suitable for one of the process media. Semi-welded heat exchangers alternate welded channels and traditional gasketed channels and can also take a higher design pressure compared to fully gasketed plate heat exchangers.

Learn more about Semi-welded gasketed plate heat exchangers

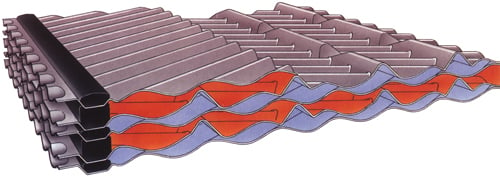

WideGap gasketed plate heat exchangers are designed for fibrous fluids and for fluids containing coarse particles. The wide gaps between plates allow fibers and particles to easily pass through the heat exchanger with minimal clogging.

Learn more about WideGap gasketed plate heat exchangers

AlfaVap semi-welded heat exchangers are rising film plate evaporators and are suitable when concentration and viscosity of media are high.

AlfaVap’s advantage is they work also when the temperature differential between the hot and cold fluids approaches as low as 4.5°F meaning that lower grade steam and more effects in series can be use in an evaporation system compared to the shell-and-tube systems.

Learn more about AlfaVap plate evaporators

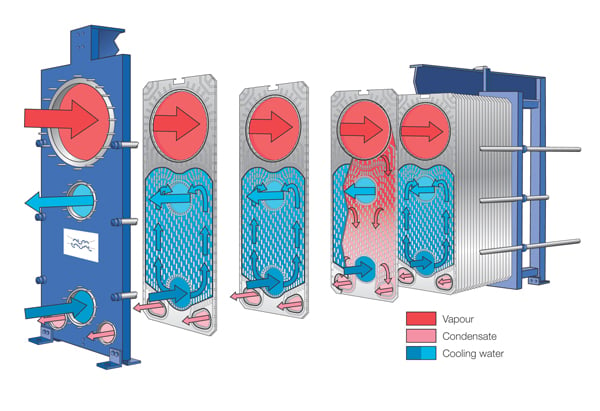

AlfaCond plate condensers are specifically designed for condensing of vapor under vacuum. They're an alternative to direct condensers when condensate recovery is the goal and when there are space constraints. Non-condensables are removed from the condensate outlet pipe and led to the vacuum system.

Learn more about AlfaCond plate condensers

Diabon plate-and-frame heat exchangers are used for highly corrosive media, combining high-efficiency heat transfer benefits with the exceptional corrosion resistance of graphite material.

Diabon is a dense, synthetic resin-impregnated high quality graphite with a fine and evenly distributed pore structure, and can be used with corrosive media up to 390°F.

Learn more about Diabon plate heat exchangers