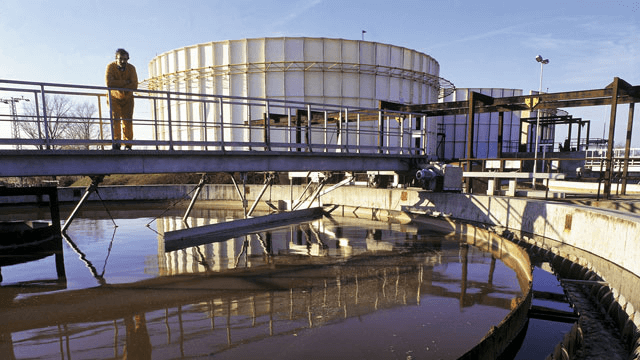

Lab and pilot testing for municipal and industrial water and wastewater

Test your sludge to achieve optimum results

Achieving the sludge thickening and dewatering results you want is important. To ensure that the solution you choose will have the results you need, Alfa Laval has a full testing lab to determine the best solution for your specific application. Pilot equipment may also be available for field testing, depending on the application.

Why test your sludge at Alfa Laval’s full testing lab?

- Whether a new application, retrofit, or a change in process, testing ensures you are provided with the best solutions

- Sample can be tested for performance for a range of different technologies – to help identify optimum equipment for your process

- Testing can determine process changes that can be made to improve performance

- When testing a representative sample of sludge, a performance guarantee can be made

The lab testing process

Your sample will arrive at Alfa Laval’s ISO 9001 certified lab in a specialized sample container (provided to you by Alfa Laval). Sludge characteristic testing (solids, pH, temperature, volatiles, etc.) will be the first step to verify properties. Polymer screening will then occur to investigate performance and flocculation properties of the sludge for a range of different polymer options. Then the product/polymer combinations will be tested for a variety of equipment types to help determine technology options.

Finally, a full report will be created detailing the characteristics determined, as well as polymer and equipment recommendations. Complete testing takes 1-2 business weeks.

Testing Standards

The Alfa Laval testing lab in Houston, TX follows Standard Method 2540 procedures.

Technologies that can be evaluated for your application

Alfa Laval has a full range of sludge thickening and dewatering products including:

Pilot testing available

-

Test a product in your facility to experience different scenarios

-

Allows you to try equipment directly on your process

- Pilot trailers available for centrifuge, belt press, rotary drum thickener, and Iso-Disc® cloth media filter units

-

Certain costs may apply depending on test

Interested in lab testing or pilot testing for your facility?

Contact your local Alfa Laval regional manager to initiate a conversation about your application

You may also be interested in:

Wastewater webinars on demand

Learn about the key fundamentals of secondary biological and tertiary treatment and the solutions for increasing available water resources, reducing intake of new water, limiting effluent flow loads to sewers and minimizing costs.