Gasketed plate-and-frame heat exchangers

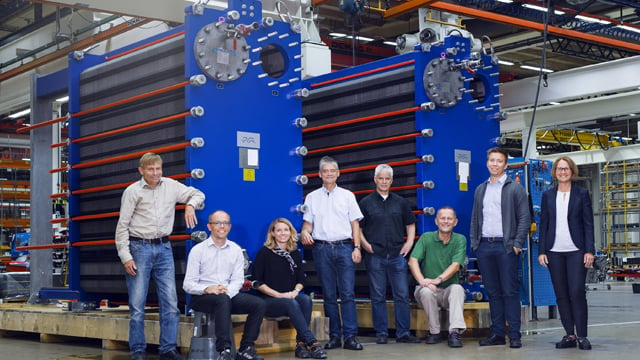

Alfa Laval offers exceptional heat exchangers tailored to meet specific needs, including a diverse industrial range, semi-welded options for refrigeration and precision processes, hygienic solutions for food, beverage and pharma, and specialized units for condensation, evaporation, and fibrous media. Buying with Alfa Laval ensures access to cost-effective, efficient, and secure heat transfer solutions.

Gasketed plate heat exchanger benefits

- Precision heat transfer – closer approach temperature, true counter current flow, 80-90% less hold-up volume

- Low overall cost – low capital investment, reduced installation costs, limited maintenance and operating costs

- Maximum reliability – less fouling, stress, wear and corrosion

- Environmentally responsible – minimum energy consumption for maximum process effect, reduced cleaning

- Easy to expand capacity – simply add or remove plates on the existing frame

Efficient heat transfer

Gasketed plate-and-frame heat exchangers (GPHEs) provide efficient heat transfer in compact equipment with a small footprint – much smaller and more efficient than shell-and-tube heat exchangers. Our wide range of products is used in duties for heating, cooling, heat recovery, evaporation, and condensation in industries such as HVAC, refrigeration, engine cooling, dairy and food, chemical processing, oil production, power generation and more.

Plate heat exchangers are designed to optimize heat transfer, because the corrugated plates provide by far the greatest surface area through which the heat can be drawn from one gas or liquid to the other. The units also have a flexible design and are easy to service and maintain.

Contact an expert

To learn more about your options or to get advice from our experts about which gasketed plate heat exchanger is the best fit for your business, contact us now.

How GPHEs work

The concept behind a heat exchanger is relatively simple – heating or cooling one medium by transferring heat between it and another one.

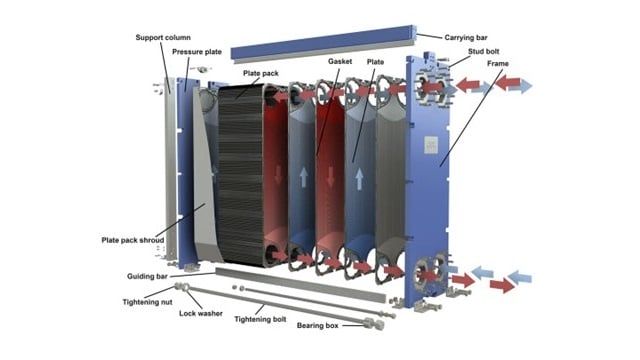

In a gasketed plate heat exchanger, the plates are fitted with elastomeric gaskets which seal the channels and direct the media into alternate channels. The plate pack is assembled between a frame plate and a pressure plate and compressed by tightening bolts fitted between these plates. The channel plates and the pressure plate are suspended from an upper carrying bar and fixed in position by a lower guiding bar, both of which are fixed to the support column. The design allows easy cleaning and simple capacity modification (by removing or adding plates).

The heat transfer area of a gasketed plate heat exchanger consists of a series of corrugated plates, assembled between a frame and pressure plates to retain pressure. Gaskets act as seals between the plates.

Fluids normally run counter-currently through the heat exchanger. This gives the most efficient thermal performance and enables a very close temperature approach, i.e., the temperature difference between the exiting process medium and the entering service medium. For heat sensitive or viscous media, co-current flow can be used to let the coldest fluid meet the hottest when entering the heat exchanger. This minimizes the risk of the media overheating or freezing.

Our thermal design engineers can help you design and select the model and configuration that is suitable for your application so that it delivers maximum thermal performance with minimum pressure drop.

Access tools and continuing education

GPHE heat transfer theory and calculations

Use our plate heat exchanger calculation method to determine the right heat exchanger for your thermal problem or needs. The Alfa Laval product range of plate heat exchangers is extensive, and every single heat exchanger can perform a range of duties. Applications include the heating and cooling of different fluids in factories, HVAC applications, process cooling, components in air conditioning equipment, etc.

Find us in MasterSpec

To help your specification needs, we offer you the latest and greatest product specification information via MasterSpec.

Unsure about certifications?

An AHRI-certified gasketed plate heat exchanger ensures that operation will perform exactly as intended. Checking the AHRI Certification Library is always recommended when designing projects.

Looking for a 3D File?

You can find 3D blueprints of Alfa Laval products for the most used design platforms in the BIM gallery.

Downloads

By product

By industry

By service

When you buy Alfa Laval equipment, you buy peace of mind

Alfa Laval provides expert maintenance, repair and troubleshooting services for heat exchangers throughout their operational life, to ensure peak efficiency and prevent potential issues. In the event of a malfunction or parts failure, our team of skilled technicians is readily available to address concerns promptly and provide genuine spare parts, minimizing downtime and optimizing performance. With Alfa Laval's service offerings, you can trust in the continued efficiency and smooth operation of your heat exchanger for years to come.

How to properly service your plate and frame heat exchanger

Watch heat exchanger experts Lauren Mitchell, Kristi Smith and Cosimo Pecchioli demonstrate how to properly open, install plates and close your plate and frame heat exchangers. Engagement on this event was the highest we've seen, so you won't want to miss it!