Tank Cleaning - Accessories

Manway Adapter

The Alfa Laval Manway Adapter was designed specifically for the transportation industry to speed up the tanker cleaning process and create a safer environment for employees by eliminating the splashing of hot water and chemicals used in the cleaning process. The cone shape allows for easy placement and complete sealing.

Product benefits

- Perfect seal: Seal any round opening and prevent splashing during cleaning cycles.

- Quick insertion into tanker manways: Specifically designed for tankers and rail cars

How it Works:

Alfa Laval tank cleaning machine gets threaded onto the bottom 2 in. NPT Male Inlet. The adapter is then placed through the top of the manway opening and lowered into the tank. The cone-shapped "stopper" will retain the cleaning spray inside the tank and prevent burns to the personnel (caused by hot water or caustic solutions), prevent short circuits to exposed electrical equipment and prevent the accumulation of ice when used in cold climates.

Rotacheck

The Alfa Laval Rotacheck is a highly innovative machine designed to validate the rotary impingement cleaning process inside sanitary tanks. Compliant with 3-A and EHEDG standards, the Rotacheck fulfills the demands of cleaning verification in the brewing, pharmaceutical, personal care, food and beverage, and dairy processing industries. During CIP, the Rotacheck stores time and pressure data, automatically calculating the cleaning process’s feedback. A light indication is integrated into the field housing offering this visual feedback to operators and maintenance staff on site.

Benefits

- Safe, hygienic and validated tank cleaning

- Easy rotary jet head monitoring

- Intelligent sensor

- 3A and EHEDG compliant

- Uses patented technology

- Provides immediate visual feedback

Verification of the rotation of rotary jet heads

The Alfa Laval Rotacheck is an intelligent sensor that validates the rotation of the Alfa Laval rotary jet heads during the tank cleaning operation. Designed for use in all types of hygienic tanks, it is approved to carry the 3-A symbol and the European Hygienic Engineering & Design Group (EHEDG) symbol.

It is available in two versions, Rotacheck Basic and Rotacheck+, both of which are approved for use in potentially explosive environments in Zone 0/20 in the product wetted area and Zone 2/22 in the non-product wetted area.

Safe, hygienic and validated tank cleaning

The Alfa Laval Rotacheck is built upon patented technology and mechanical design. It features a special sensor that accurately and precisely registers, monitors and evaluates the rotation and impact of the rotary jet head. Whenever any deviation from the original rotation or impact pattern is detected, it automatically sends an error signal, enabling the control system as well as the operator to take remedial action to restore optimal operation.

The Rotacheck system may also be used with PW (purified water) and WFI (water for injection) as well as in systems that are pressurized during CIP.

Easy rotary jet head monitoring

With Alfa Laval Rotacheck, plant operators and maintenance staff can easily monitor and verify proper rotary jet head function as well as safe and efficient tank cleaning operations. A visual indication light integrated into the field housing displays the status of the rotary jet head. Digital outputs enable effortless connection to any control or PLC-system, providing secure online monitoring of tank cleaning operations at the plant at all times.

Truly hygienic tank cleaning

The Rotacheck system uses the Alfa Laval Hygienic tank connection, which minimizes microbiological build-up and ensures a fully flushable process connection. EHEDG-approved and authorized to carry the 3-A symbol, the HTC connection is one of Alfa Laval’s new hygienic process connections.

Rotary jet head tank cleaning verification

The Alfa Laval Rotacheck system for rotary jet head tank cleaning verification and validation is available in two versions:

- Rotacheck+, an advanced system with a built-in function for validation of the rotary jet head.

- Rotacheck Basic, a standard system suitable for validating the rotation of the rotary jet head and for retrofitting of Rotacheck systems that are already installed.

Inlet Connections

In continuing Alfa Laval's mission to provide customers with complete tank cleaning solutions, we offer a wide variety of inlet connections, either standard or custom design. Standard designs include Tri-Clamps, NPT's, R-clips and camlocks of varying sizes. Custom designs include extended inlet shafts welded directly to the Alfa Laval tank cleaning machine to ensure a tight sanitary design. Custom flanges or sanitary caps of any size and manway covers, etc. are available.

Portable cleaning cart

There are two types of cleaning solutions, portable and permanently installed. Facilities which require cleaning at a high frequency tend to utilize a permanently installed Alfa Laval tank cleaning machine, whereas facilities that clean less regularly lean towards a portable tank cleaning solution. This allows for the purchase of one unit, to clean a variety of tanks. However, the design of a tank, rarely incorporates clean-ability, meaning inlets and entry ways are rarely in an ideal location for optimal cleaning. For portable tank cleaning applications, regular tank entry, or climbing to the top of a tank to suspend the Alfa Laval Portable Tank Cleaning Machine could become burdensome and counter productive. As a result Alfa Laval has come up with the Portable Cart or Alfa Laval Tripod.

Product benefits

- Safe, Portable Tank Cleaning Solution: Reach the center of a tank with a side man-way without confined space entry

- Variety of Applications: Wine, brewing, chemical, food and beverage and more.

How it Works

Attach the Alfa Laval tank cleaning machine on the top 2 in. NPT Male inlet or camlock fitting. Next, attach your hose on the side 2" NPT Male Inlet or 2” TC. Once everything is in place the device may be rolled to the desired cleaning location within the tank.

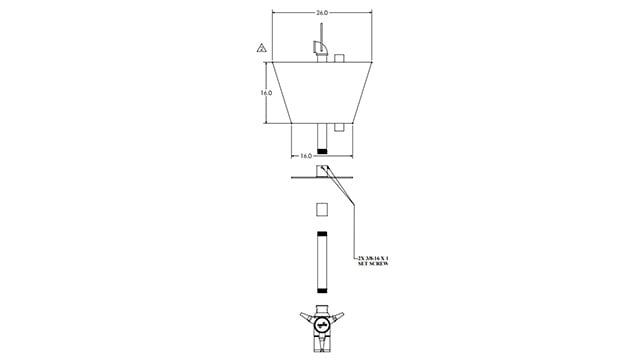

Tripod

There are two types of cleaning solutions, portable and permanently installed. Facilities which require cleaning at a high frequency tend to utilize a permanently installed Alfa Laval tank cleaning machine, whereas facilities that clean less regularly lean towards a portable solution. This allows for the purchase of one unit, to clean a variety of tanks. However, the design of a tank, rarely incorporates clean-ability, meaning inlets and entry ways are rarely in an ideal location for optimal cleaning. For portable applications, regular tank entry, or climbing to the top of a tank to suspend the tank cleaning machine could become burdensome and counter productive. As a result Alfa Laval has come up with the Alfa Laval Gamajet Portable Cart or Alfa Laval Gamajet Tripod.

Product benefits

- Adaptable portable tank cleaning solution: Used for tanks with sloped or conical bottoms or have build up residues/sludge on the bottom.

- Variety of applications: Wine, brewing. chemical, petroleum, pulp and paper

How it works

The Alfa Laval tank cleaning machine gets threaded on to the top center NPT Male Inlet while your hose gets threaded on the bottom side NPT Male inlet. The tripod is then simply placed through the manway, legs are separated and then tripod is placed in desired location for cleaning.

GJ Sidewinder

For many years, the standard cleaning method for tanker washes has involved the insertion of vertically-placed tank spinners through the center manways of trailers. While this method is common and widely accepted, rarely are the ends and bulkhead areas sufficiently clean enough to prevent cross-contamination. Fortunately, we have created a customer-driven solution for cleaning the typically difficult-to-reach bulkheads of any type or size OTR tankers: The Sidewinder. This device is a revolutionary, affordable accessory for achieving the most effective and efficient tanker, trailer, and railcar cleaning. Enabling an Alfa Laval tank cleaning device to be placed on its side, it completely changes the nature of the nozzles’ orbit. Instead of creating an ellipse pattern across the tank wall, the Sidewinder enables the machine to form a figure-8 pattern sweeping the length of the tanker, increasing the number of hits to the bulkhead by 30 times, and cleaning the tanker in half the time. Coupled with an GJ 8 or GJ 4, which are designed to easily handle 20-30 ft. throw lengths, the Sidewinder enables your wash station to provide the most efficient and effective clean to every inch of the trailer.

Product benefits

- Delivers 30 times more hits to bulkheads

- Cleans tanker in half the time

- Self-balancing capability to maintain revolution control

- Compatibility with facility’s existing pressures and flows

- No shadow areas after cleaning

Bipod

For barrel cleaning bung hole down. Barrel cleaning has evolved immensely from the days of fill and drain. Automated barrel cleaning machines have been used more and more, making the process much easier. The Bipod was designed to allow for fast and easy placement of GJ BB and GJ 7. Its unique folding capability gives it the maximum clearance and stability for prompt and reliable placement withing the barrel.

Specifications

- Materials: 316L Stainless Steel; Nylon Feet

- Length: 20 in. (.5m)

- Width: 7.5 in. (190 mm)

- Height: 5 in. (130 mm)

- Weight: 4 lbs (2 kg)

- Inlet Connections: 3/8 in. (12 mm) NPT-Male

How it works:

The 3/8 in. NPT Male Inlet collar gets threaded on center feeding tube. The Alfa Laval tank cleaning machine is than threaded on the 3/8 in. NPT Male Inlet collar for a secure upright hold. The Alfa Laval tank cleaning machine is placed within the bung hole, with the legs folded back for extra clearance. Once under the barrel, the legs are pulled back and unfolded to rest either on the ground or the barrel beneath.