Reducing cooling costs and emissions in agricultural chemical production

In the agricultural chemical industry, as in many others, production efficiency and environmental impact are constant concerns. An Indian agricultural chemical producer faced a cooling challenge with their shell-and-tube heat exchangers. By partnering with Alfa Laval, the company eliminated the need for 118,000 m3 chilled water/year, achieving significant cost savings and environmental benefits, with a payback time of less than one year.

DATE 2025-10-30MDC – a common solvent requiring precise cooling

India is a major producer of agricultural chemicals. These facilities often depend on batch processes and flexible production lines to manage a variety of chemicals. A widely used solvent is dichloromethane, or methylene dichloride (MDC), which must be condensed at atmospheric pressure and low temperature. This makes cooling efficiency a critical part of the process.

Pushing the limits of conventional technology

One of India’s agricultural chemical producers used shell-and-tube heat exchangers to condense MDC vapours. The customer had cooling water at 34 °C, but the MDC vapours needed to be cooled from 39.5 °C to 35 °C. The small temperature difference of just 1°C was too narrow to ensure effective condensation with their existing technology.

Instead, the plant opted for chilled water at 20 °C. This solution came at a high cost: producing chilled water not only requires electricity, increasing operational costs, but also contributes to CO2 emissions.

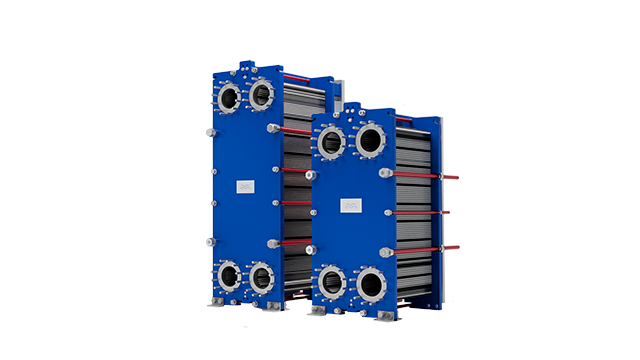

Semi-welded heat exchanger eliminated the need for chilled water

This technology is designed to handle small temperature approaches efficiently, allowing the plant to utilize the existing 34 °C water, completely eliminating the need for chilled water.

The results were impressive, with significant annual savings:

- 118,000 m³ of chilled water

- 228 MWh of electricity

- 161 tonnes of CO2 emissions

All achieved with a payback period of less than one year.

This seemingly small change has proven so successful that it is now considered best practice. Similar plants are expected to follow suit, replacing traditional shell-and-tube heat exchangers with solutions that provide more efficient heat transfer, like Alfa Laval’s semi-welded plate or spiral heat exchangers.

Tags

All