Data center cooling

Energy efficient cooling is critical to building more sustainable data center operations. Alfa Laval has been a trusted partner to the IT industry for decades, working with customers to design reliable, environmentally friendly data center cooling systems. With 80+ years’ experience in thermal technology, we offer expertise to enable new opportunities for free cooling and energy savings in server cooling systems of all sizes, all around the globe.

Keys to sustainable data center cooling

- Advanced plate heat exchanger data center cooling technology that minimizes the need for traditional mechanical cooling

- Unique data center cooling solutions that maximize efficiency for minimized energy consumption and environmental impact

- A wide range of data center solutions to boost sustainability by taking advantage of free cooling and heat recovery opportunities

- Innovations for improving reliability and serviceability help you maximize uptime and simplify maintenance

- Third-party AHRI certification offers confident assurance of a heat exchanger’s thermal performance

1. Cooling tower interchanger

2. Free cooling with water

3. Free cooling with air

4. Heat recovery

5. Liquid cooling

6. Edge data centers

Optimize your data center’s efficiency and savings

Explore how Alfa Laval’s cutting-edge cooling products can help your data center achieve maximum energy efficiency and reliability. From compact gasketed plate heat exchangers to engineered air coolers, discover the technology that powers sustainable cooling.

Protecting and enabling greener solutions

On average, as much as 40% of a data center's power consumption goes toward cooling the servers. Fortunately, the technology to make these data center cooling systems more energy efficient and reliable already exists. Watch this video to learn about the potential for increased sustainability with Alfa Laval's next-generation plate heat exchangers for data centers.

Do you need BIM files?

Heat exchangers from Alfa Laval are now available in the digital infrastructure for BIM objects. Preview and download building information modelling (BIM) files for your heat transfer solutions.

Innovative two-phase, direct-to-chip liquid cooling solution

SEGUENTE, Inc., has developed a two-phase, direct-to-chip liquid cooling solution utilizing Alfa Laval brazed heat exchangers as condensers inside the unit. Scalable, highly efficient and cutting-edge, the SEGUENTE COLDWARE™ system is groundbreaking in delivering enhanced data center performance, cost savings and sustainability.

Efficient and reliable data center cooling technology

Only Alfa Laval offers a full range of heat transfer technology for data center HVAC with performance certification from the independent Air-Conditioning, Heating, and Refrigeration Institute (AHRI). This gives you confident assurance of efficient performance, but the equipment is just the beginning. Find out how we can work with you from day one to make sure your data center cooling system will deliver reliable, long-term sustainability.

Questions? Challenges? Support? Don’t worry – that’s what we’re here for.

Want to find out how the right cooling technology can help your data center achieve greener goals? Fill out the form, and one of our experts will get in touch with more information.

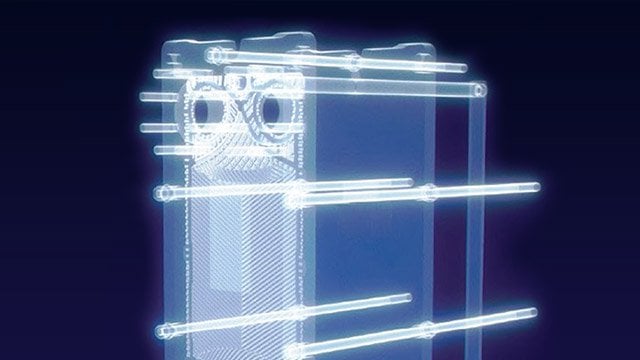

Gasketed plate-and-frame heat exchangers

Alfa Laval’s next generation of industrial gasketed plate heat exchangers sets new standards of thermal efficiency, mechanical reliability and ease of serviceability. It is the key to more sustainable data center cooling methods.

Brazed and fusion bonded plate heat exchangers

Alfa Laval has the market’s most comprehensive line of brazed plate heat exchangers, with a range of solutions for data center cooling optimized for today’s more sustainable, natural refrigerants. Discover how you can benefit from ‘more with brazed’.

Cylindrical filter baskets

Alfa Laval offers a range of automatically self-cleaning filters and strainers, used to protect heat exchangers in data center cooling systems from clogging, fouling and corrosion. Reduce the risk of unplanned downtime and prolong service intervals.