AlfaFlash

The Alfa Laval AlfaFlash flash evaporator is designed to concentrate efficiently high-viscosity, high-fouling, and shear-thinning fluids, safely, reliably, effectively. Compact, self-cleaning and easy to maintain, this flash evaporator excels in handling process liquids with high suspended solids content, meeting medium to zero liquid discharge requirements. Suitable for applications, from proteins, food, beverage, starch, and sweeteners to life science and industrial fermentation to wastewater.

Concentrate high viscosity, fouling-prone and shear-thinning fluids with ease

- Maximum uptime due to minimal fouling as a result of a higher shear rate and higher turbulence, which creates a self-cleaning effect

- Minimized disposal and transport costs due to highly efficient concentration of high-viscosity or shear-thinning process liquids

- Compact, space-saving footprint due to reduced height and weight compared to shell-and-tubes, cutting installation, operating and maintenance costs

- Excellent preconcentration and turndown capabilities due to energy-efficient dryers and adjustments to varying feed composition during recirculation

- Perfect for boosting capacity and debottlenecking existing evaporation systems

Versatile, compact, and self-cleaning, the Alfa Laval plate flash evaporator is effective for a broad range of applications with high viscosity, fouling-prone process liquids with high-solids content, such as supersaturated salt solution and olive mill effluent. Perfect for new or retrofit installations, these evaporators meet medium- to zero-liquid discharge requirements across all industries.

- The BlueVap system is an automated, pre-assembled solution that concentrates olive mill black water. By separating the water into 80% clear water and 20% biodegradable cake, this system eliminates the need for steam or cooling water, offering a sustainable solution to high-solid content effluents.

- The AlfaFlash system is a forced circulation evaporator that concentrates challenging process liquids with suspended solids and some crystallization

It’s a hundred times better than the old system! Apart from a scheduled summer close-down, it has run without interruption, producing the quality and consistency of Pot Ale we want. We clean the units in place by flushing at the end of each week and when we inspected the heat transfer surfaces during the summer shut-down, they were clean as a whistle.” – Shane Fraser, Distillery Production Manager, Glenfarclas Distillery

Alfa Laval helps us reach our goal of a zero-waste olive oil production with BlueVap.’ –Owner, Frantoio di Santa Téa, Reggello, Italy

How a plate flash evaporator works

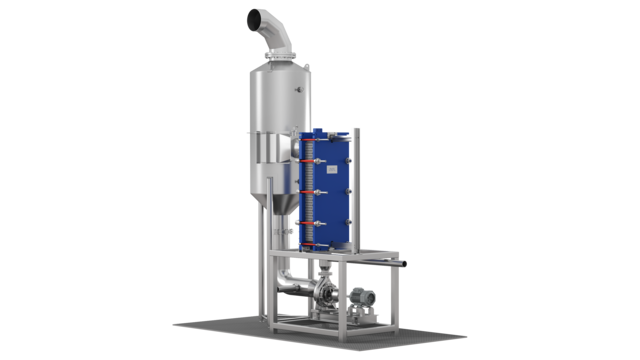

The Alfa Laval AlfaFlash plate flash type evaporator is a forced circulation flash evaporator. A pump recirculates the liquid between the cyclone separator vessel and the plate flash evaporator, creating a highly turbulent flow inside the flash plate heat exchanger.

Boiling does not take place in the plate heat exchanger but rather the liquid is heated under pressure. The actual evaporation takes place when the heated liquid is discharged to the separator vessel where the pressure is released and the volatile liquid then flashes. Many AlfaFlash applications run under vacuum.

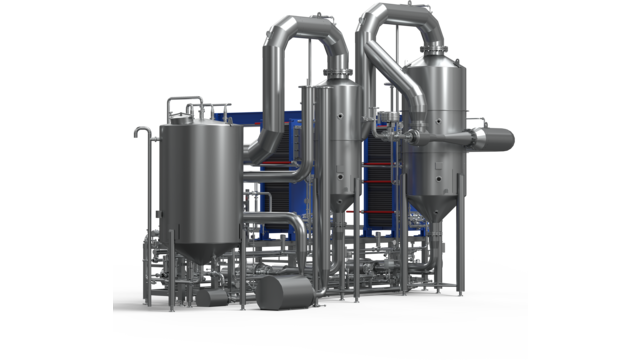

Multi-effect designs reduce the steam consumption requirements: the vapour produced in one effect is used as the heating media in a subsequent effect. In combination with thermal vapour recompression (TVR) and/or mechanical vapour recompression (MVR), the steam consumption can be reduced to a fraction of the evaporation capacity.

A complete AlfaFlash system includes the plate evaporators, preheaters, separator vessels, TVR or MVR, recirculation pumps, instruments, valves, ducting, piping, and a control panel.

Perfect for non-Newtonian fluids

The AlfaFlash flash evaporator features a corrugated plate design that generates turbulence and promotes continuous cleaning, preventing rapid fouling compared to traditional shell-and-tube flash evaporators. Additionally, for shear-thinning products like stillage, corn steep liquor, and protein solutions, the high shear generated by the AlfaFlash flash plate evaporator reduces the apparent viscosity of the process liquid. This not only minimizes fouling but also enhances heat transfer efficiency.

Rising Film Evaporator compared to Shell-and-Tube Evaporator

Compared to a traditional shell-and-tube evaporation system, the AlfaFlash and AlfaVap systems require substantially less installation height and can be installed without complex civil work on site. The AlfaFlash flash evaporator, with its advanced flash evaporation method, offers significant advantages over conventional systems. The compact design of the AlfaFlash plate flash evaporator ensures efficient operation and easy maintenance, making it ideal for various industrial applications.

By utilizing the flash evaporation method, the AlfaFlash flash plate evaporator minimizes fouling and enhances heat transfer performance. This makes it a superior choice for processes involving high-viscosity and high-fouling liquids. The AlfaFlash system's ability to handle challenging process liquids with suspended solids and some crystallization further sets it apart from traditional shell-and-tube evaporators.

Heat sources for evaporation systems

Configuration Options

Alfa Laval evaporation systems can use heat from different sources such as mechanical and thermal compression as well as waste vapours from dryers.

Multiple-effect system

- Saves energy by reusing steam

- Simple and flexible

Mechanical vapour recompression, MVR

- High investment

- Low (or no) steam consumption

- Uses electricity

Thermal vapour recompression, TVR

- Low cost with reduced steam consumption

- Simple, no moving parts

Waste heat from dryers

- Low energy cost

- Relatively high investment

Happy customers

Pilot testing and rentals of evaporation systems

Try before you buy. Get expertise and advice from Alfa Laval engineers for the optimum configuration for your evaporation system, including:

- Detailed water analysis and characterization

- Process and water chemistry modelling

- Benchmark and/or pilot testing for moderate- to high-risk applications

- Detailed material compatibility evaluation

- Sample analysis

- Pilot tests

Visit the Alfa Laval Materials Technology & Chemistry Lab and Test Centre in Lund, Sweden, the Alfa Laval Innovation and Test Centre in Nakskov, Denmark, or rent one of our mobile pilot evaporation systems to conduct onsite trials at your plant.

Key products

Service

Food system services

Alfa Laval Food system services help extend the performance of your food systems by maximizing the performance of your processes. This enables you to:

- Continually improve your operations to maintain competitive advantage

- Focus on uptime, optimization and availability

- Maximize return on investment throughout the life cycle of your food systems

Engineered system

A complete AlfaVap climbing film evaporation system includes plate evaporators, preheaters, cyclone separator vessels, thermal and/or mechanical vapour recompression units, pumps, instruments, valves, ducting and piping and a local programmable logic controller (PLC) and control panel. The system can be pre-assembled in Alfa Laval’s workshop, which reduces installation time on site to one to three weeks.

You might also be interested in...

Explore our range of evaporators

Alfa Laval offers a wide range of evaporation systems from plate evaporators, and rising film evaporators to tubular evaporators and falling film evaporators. Find out what would work for your evaporation needs.