Sigma

The Alfa Laval Sigma series of olive oil decanter centrifuges for two-phase separation help you improve quality and increase yield. Maximize oil recovery throughout the flow range whilst minimizing environmental costs. These compact, reliable and efficient olive oil decanter units are ideal for clarification, extraction, sludge watering and classification on the first and second extraction (remilling).

A full spectrum of olive oil production market needs

With the introduction of the Alfa Laval Sigma 6 and Sigma 8 to supplement the existing Sigma 9 and Sigma 10 models, Alfa Laval now covers the full spectrum of market needs. Whether you are a small-scale olive oil miller or an industrial-scale producer, Alfa Laval’s passionate experts can help you increase capacity and profitability. Our proven olive oil extraction machines, alongside industry knowhow and an extensive global service and support network, promise reliable production throughout every season.

The De Carlo case story

For the last 50 years, the family-run olive oil producer De Carlo in Bitritto, Italy has been using Alfa Laval’s olive oil production equipment, including the latest Sigma 6 especially designed for small-scale olive oil mills. Watch the video to see how they improve the quality of their olive oil, optimize costs, and reduce the consumption of water.

The Sociedad Agricola Ouro Vegetal (SAOV) case story

In this video, the award-winning Portuguese olive oil producer Sociedad Agricola Ouro Vegetal (SAOV) reveals how they handle the biggest challenges faced in the last 3-4 years, that is, to meet the recent increase in extra production while maintaining a high-quality standard for their olive oil.

Sigma decanter centrifuge design benefits:

- Feed zone position that maximizes the time the oil spends inside the unit, and how much oil is extracted

- Special conveyor design that improves solids transport and maximizes oil recovery

- Special flights to prevent turbulence as the oil moves towards the liquid outlet, to optimize yield and oil clarification

- Surface level of olive oil outlets ensure minimal heating of the oil during separation, helping protect oil quality

- Special bowl design with easy oil discharge minimizes the quantity of oil held inside the bowl

- Fully protected feed zone, featuring a special design that improves resistance to wear

- 360° solids discharge outlets made of tungsten carbide, which provides exceptional protection against wear and keeps power consumption to a minimum

- Conveyor fitted with tungsten carbide tiles (standard on Sigma 8, 9 and 10; optional on Sigma 6) to provide wear protection that significantly reduces maintenance costs

- Conveyor parts subject to high wear are easy to replace

- Easy serviceability

- Cover is equipped with hinges and springs to make it easy and safe to open, clean and inspect the decanter

Automation

Decanter centrifuges in the Sigma range are equipped with a variable frequency drive (VFD) and are available with control solutions to comply with your specific operating requirements.

Connectivity

Sigma decanter centrifuges can also be fitted with IoT equipment, to provide users and decision-makers with a wide range of operating data, whether onsite or off.

- Remote support enables your service provider to provide remote troubleshooting to help ensure maximum processing uptime and keep your Sigma unit or units running throughout the hectic olive processing season

- Remote monitoring ensures greater peace of mind. Access Alfa Laval´s connectivity portal to remotely monitor your decanter centrifuge and receive any appropriate alarm notifications

A well-run predictive maintenance plan will help you correct small service issues well before they turn into major problems. This can save you time, money, and the stress of an unplanned shutdown. Learn how to make the change in this on demand webinar.

How it works

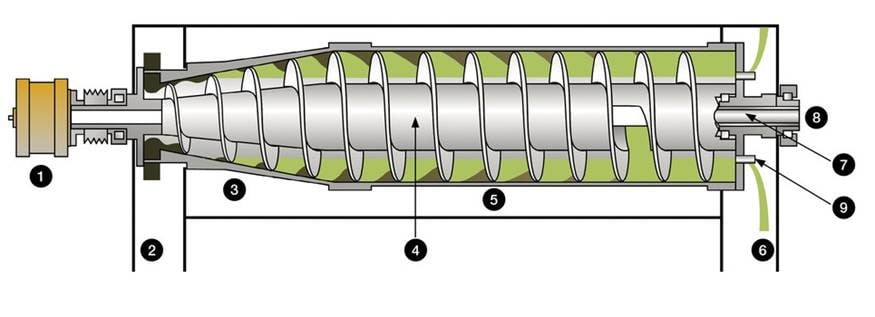

- Gearbox

- Wet husk outlet

- Conical end

- Screw conveyor

- Bowl

- Olive Oil outlet

- Feed tube

- Feed inlet

- Oil discharge ports

Sigma olive oil decanter centrifuge operating principles

The Sigma olive oil decanter centrifuge design makes sure the incoming paste is effectively separated into oil and wet solids.

The olive paste is fed into the bowl of the unit through a stationary inlet tube, and is then smoothly accelerated by an inlet rotor. Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. Centrifugal force makes the oil accumulate at the liquid surface, while the solids settle on the inner wall of the bowl, surrounded by the water separated out of the feed stream.

The conveyor rotates at a slightly different speed than the bowl and moves the solids to the discharge ports in the conical end. Olive oil extraction takes place along the entire length of the cylindrical part of the bowl. The oil is returned to the large end for discharge, and then passes into collecting tanks via a filter.

The Alfa Laval Sigma range of olive oil decanter centrifuge:

Sigma 6

For small-scale olive oil producers

Sigma 8

For industrial-scale olive oil producers

Sigma 9

For industrial-scale olive oil producers

Sigma 10

For industrial-scale olive oil producers