Webinar: How to move from preventive to predictive maintenance of your decanter centrifuge

View this webinar on demand

We all know what a headache an unplanned shutdown can be. From equipment repairs to late or unfilled orders, the costs could end up in the tens of thousands. What if there were a way to predict problems in your decanter centrifuge before they happened?

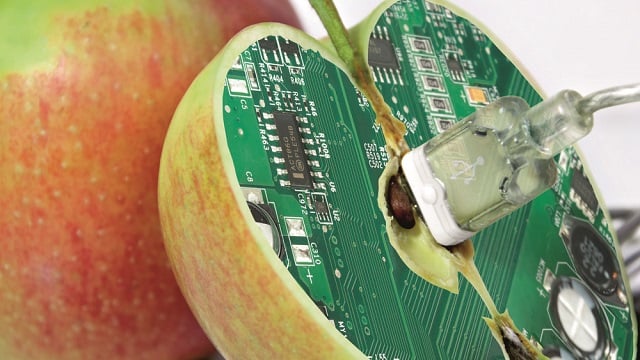

This short webinar introduces Alfa Laval’s condition monitoring system, ConditionAlert TM. This state-of-the-art technology monitors your decanter centrifuge 24/7 and identifies early-stage defects in the main bearings and conveyor bearings. You’ll receive an early warning of defects and a service recommendation well before problems arise so you can take action before a small issue turns into a major catastrophe.

What you’ll learn:

- Why predictive vs preventive maintenance?

- How can businesses use data to make better decisions?

- How to decide when it’s the right time for predictive maintenance

You may also be interested in:

Maximize operating reliability with Alfa Laval IoT Services

Alfa Laval’s IoT Services is a range of digital services that maximizes operating reliability and uptime in food & beverage processing plants.

Minimize operating cost with Alfa Laval IoT Services

Alfa Laval’s IoT Services is a range of digital services aiming to reduce operating costs and maximize operating reliability in wastewater plants.