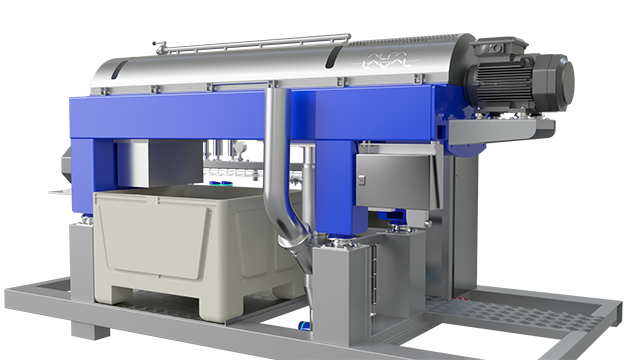

Foodec

The Alfa Laval Foodec decanter centrifuges are ideal for applications where efficiency and easy cleaning are crucial in processing food and beverage products. From protein and dairy to beverages, fats, vegetable oil, starch and industrial fermentation, the Foodec portfolio is extensive yet carefully engineered for industries that requires an enclosed machine and continuous operation.

Experience how Foodec decanters optimize centrifugation in food processing

- High-performance separation, resulting in high-value end products and low waste management costs

- Easy and fast CIP cleaning with Alfa Laval’s advanced technology and smart control system

- Energy-efficient drive system with significantly lower power consumption than alternative technologies

- Low maintenance costs thanks to continuous operation, high-grade machine materials, innovative design and well-plannedpreventive services

- High operational flexibility to adapt to different processes and raw materials

Optimized for maximum yield

Available in two- or three-phase configurations, Foodec decanter centrifuges help maximize yield, extraction rates, cake dryness and liquid clarification. The right food centrifuge model depends on your raw material composition and process requirements, ensuring the best possible performance. With the ability to handle varying feed rates, solids concentrations and temperatures, Alfa Laval's range of decanter centrifuges for food and beverage processing easily adapts to changing production needs.

Innovation that drives results

With decades of expertise and continuous innovation, Alfa Laval centrifuges are well known for their simplicity, reliability and long lifetime—even in harsh environments. They also optimize the recovery of valuable by-products, such as proteins, spent grains and oil fractions, helping you create new revenue streams from existing processes while reducing waste.

Features that make the difference

Everything you need to meet your challenges today and tomorrow

With unique Alfa Laval features, our decanter centrifuge for food applications offers improved efficiency, reliability, and ease of maintenance across the food industry. Alfa Laval's unique features are designed to meet your specific needs, ensuring optimal performance and maximum uptime.

TrueStainless™

Stainless steel for long-lasting hygiene

TrueStainless™ ensures solid stainless steel is used for the frame and other key parts of your decanter centrifuge that may be in contact with corrosive atmospheres, leading to optimal hygiene and longer equipment life.

PondCtrl™

Adjustable pond depth control during operation

Fast and accurate adjustment of your decanter centrifuge pond depth, ensuring optimum conditions for maximum separation performance, cleanability and easy start-ups.

SaniRibs®

Clean, efficient way to transport solids

Unique seal welded ribs create more friction, which offers better, more efficient solids transportation. This innovative technology also eliminates pathogen hot-spots and allows for easy cleaning, meaning longer production runs, less manual maintenance, and improved profits.

FlightProtect

Protection against wear on conveyor spirals

FlightProtect is a wear-resistant coating specifically designed for conveyor flights that preserves the integrity of each flight and extends its service life.

SaniFeed

Feed zone optimized for sanitary applications

The uniquely designed SaniFeed feed zone ensures gentle product acceleration and minimal turbulence, resulting in low power consumption. The smooth, crevice-free surfaces and absence of sharp corners ensure fast and effective cleaning, and in turn maximum uptime, and a high level of hygiene.

PondCtrl – Adjustable pond depth control during operation

Take full control of your food centrifuge with Alfa Laval PondCtrl, the automated solution for regulating pond depth in real time. Designed to prevent liquid overflow in the solids discharge, optimize cleaning and adapt to feedstock variations, PondCtrl ensures higher uptime, improved yield and consistent product quality.

- Seamless starts and stops with automated pond depth adjustments

- Optimized separation for superior product quality and process stability

- No need for slide gates—automatically prevents liquid overflow

- Compatible with new and existing decanters equipped with a paring disc outlet

Fine-tune your process while your decanter is running, ensuring optimal centrifugation in food processing with the perfect balance of separation, taste and efficiency. This is especially crucial in beer and plant-based drinks production, where controlling fine fiber content directly impacts product success. With PondCtrl, you can easily adjust separation parameters on the fly, ensuring optimal taste and mouthfeel without interrupting production.

How does a food centrifuge work?

The unique design of Alfa Laval's decanter centrifuge for food and beverage processing efficiently separates the incoming feed into three phases: oil, solids and water.

The product is fed into the bowl through a stationary inlet tube and is then smoothly accelerated by an inlet rotor. Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. Centrifugal force causes instant sedimentation of the solids on the wall of the bowl.

The conveyor rotates in the same direction as the bowl, but at a different speed, and conveys the solids to the conical end. Because it is lighter, the fat or oil flows on the inside, and the solids move towards the outer perimeter, while the water remains in the middle. The two liquid phases pass to their respective outlets via a vibrating filter and are then discharged into collecting tanks.

Add value – Pond depth regulation made easy

Alfa Laval Foodec design increases hydraulic pressure inside the drum to improve flow through a narrow opening. The compacted and dewatered solids leave the bowl via discharge openings at the smaller diameter of the conical end. Separation takes place in the entire length of the cylindrical part of the bowl and the clarified liquid leaves through a paring disc (internal centripetal pump).

Traditional decanters have a pond depth limit before liquid overflows into the solids outlet. Alfa Laval's Baffle Disc eliminates this issue, allowing deeper pond operation without overflow. The disc forms a solids seal, preventing liquid from passing through. The PondCtrl system enables operators to easily regulate the liquid level and the pond depth during starts, stops and cleaning -either automatically or manually via a control panel-, ensuring maximum separation and minimizing product loss. Easily fine-tune pond depth to maintain optimal separation despite changes in feedstock composition.

All wetted parts in Foodec decanter centrifuges for the food industry are made with stainless steel. The control system is equipped with a graphic user interface and multiple communication options.

Success stories of decanter centrifuges in food and beverage processing

Optimize your production with advanced centrifugation in food processing

Because your process deserves the best engineering, our dedicated Global Service Network supports you with parts and expertise—wherever you are, whenever you need it. Elevate your Foodec’s performance and ensure maximum uptime and efficiency in food and beverage processing.

We help you achieve peace of mind, lower your total cost of ownership and maximize your return on investment.

With connected services such as remote support and monitoring, service intervals can be extended. Maintenance, repairs, condition monitoring and remote support can be bundled in a Service Agreement. Additionally, Alfa Laval also offers training programs for on-site maintenance staff.

Contact our dedicated service expert for a Service Agreement offer that is specially tailored to your needs.

Related products for food and beverage processing applications

Let us help you

Alfa Laval has been a leader in the food centrifuge market for decades. Our industry experts can analyze your unique needs and recommend the optimal equipment, configuration and services to fit your requirements and budget. Regardless of your demands or challenges, we have the right machine for you.