Dry Rendering Optimizer

Get a more protein-rich meal and higher fat yield with the Alfa Laval Dry Rendering Optimizer. Turning your existing dry rendering processing line for animal by-products into a highly efficient hybrid system or a complete, automated wet rendering system contributes to up to 40% savings in energy and operating expenditures. It can also raise the protein content in the meal by up to 5% and the yield of high-purity fat by more than 10%.

Energy-efficient rendering increases the quality and yield of protein-rich meal and high-purity fat

- Increase the protein content in meal by up to 5% while improving meal stability

- Boost fat yield by more than 10% with a higher -quality animal fat for use in biofuel production

- Cut operating and energy costs by about 40% due to automation and the reuse of waste heat

- Reduce carbon emissions through energy-efficient reuse of animal by-products, natural resources and waste heat

The Alfa Laval Dry Rendering Optimizer enhances the value of your end-product stream while boosting your sustainability credentials. Minimal investment in essential equipment results in significant cost savings. Plus, the rendering system heats animal by-products using less energy than conventional systems and reuses waste heat from drying, reducing your electricity bill.

The responsible reuse of animal agriculture resources and waste heat helps reduce carbon emissions, fossil fuel use, and utility costs – making the Dry Rendering Optimizer a wise investment.

We are always collaborating with Alfa Laval to finetune operations. We look forward to continuing our close and constructive partnership and using Alfa Laval know-how to tailor solutions to meet our requirements.”

–Salvatore Papa, General Manager, Proteg SpA

Case stories

Optimizing dry rendering processes for 40 % energy savings and improved protein and fat quality and yields

Animal fat, bone meal, and processed animal protein producer Proteg SpA approached Alfa Laval to improve product quality while reducing energy costs and environmental emissions. The request? A higher protein content to raise the sales price of protein meal for pet food, and higher quality fat for use in biofuel, which translates into a higher yield.

Service

Food system services

Alfa Laval Food system services help extend the performance of your food systems by maximizing the performance of your processes. This enables you to:

- Continually improve your operations to maintain competitive advantage

- Focus on uptime, optimization and availability

- Maximize return on investment throughout the life cycle of your food systems

Learn more about our service offer for food systems

Related products and industries

How does the Alfa Laval Dry Rendering Optimizer work?

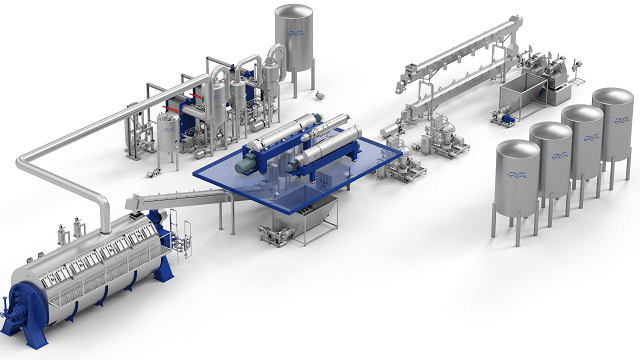

Depending on your facility’s production goals and existing infrastructure, there are two distinct upgrade paths: (1) converting a conventional dry rendering processing line into a hybrid rendering system, or (2) converting a conventional dry rendering processing line into a complete wet rendering system. Upgrading requires investment in easily integrated components, including grinders, a direct steam injection heater, pumps, decanters, high-speed separators, evaporators, and a dryer.

Upgrading option 1: Alfa Laval Dry Rendering Optimizer Hybrid

Cut energy costs and boost sustainability with the Alfa Laval Dry Rendering Optimizer Hybrid. With a minimal upgrade, you can turn your existing dry rendering plant into a high-efficiency hybrid system, reducing energy use by approximately 40%.

To achieve these energy savings and lower your carbon footprint, the upgrade includes:

- Raw material grinding and heavy-duty pumps for smoother, more efficient processing

- A DSI heater for fast, reliable heating with less energy waste

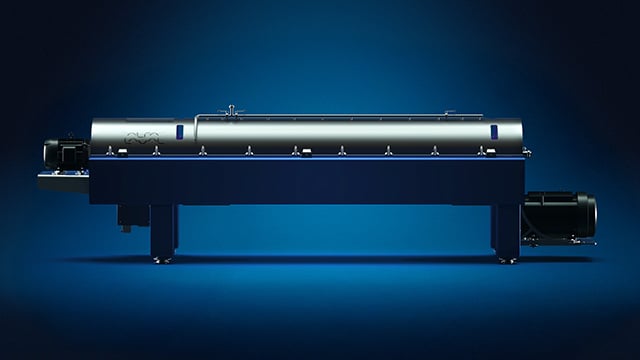

- A two- or three-phase decanter to efficiently separate water, fat, and solid (solid will be sent to the existing dry rendering system)

- A waste heat evaporator that captures and reuses heat from the cooker instead of letting it go to waste

The result: the same reliable meal and fat quality as conventional dry rendering – with the option to add a three-phase decanter for premium, wet-rendered-quality fat that can generate additional revenue through higher-value products.

Upgrading option 2: Dry Rendering Optimizer as a complete wet rendering system

Transform a conventional dry rendering line into a fully integrated, low-fat wet rendering system. This advanced solution maximizes protein recovery and improves fat purity through state-of-the-art mechanical separation.

The Alfa Laval Dry Rendering Optimizer converts an existing dry rendering processing line for animal by-products into a complete, automated Alfa Laval wet rendering system. The upgrade optimizes energy efficiency while enhancing end-product quality and yield.

To convert a conventional dry rendering line into a complete wet rendering system, the upgrade requires all raw material handling components used in the hybrid system, plus:

- An Alfa Laval fat-stripping decanter for initial fat extraction before the two-phase decanter

- A separator skimmer to remove all light-phase material from the water phase before concentration in the waste heat evaporator

Removing the light-phase material from the water phase alters the drying profile, potentially requiring careful evaluation of the existing expeller's press capacity. Alfa Laval can assess drying requirements and recommend solutions to meet additional capacity needs.

Reducing fat content in meat and bone meal allows manufacturers to achieve up to 5% higher protein than conventional dry-rendered meal, or maintain similar protein levels with lower fat content. Optimizing the moisture content also minimizes thermal damage, delivering meal yields comparable to those from dry rendering while maintaining high-quality protein.