Liquid Desiccant Dehumidification

Alfa Laval Kathabar dehumidification systems provide precise control of demanding OR (operating room) conditions needed by surgical staff that both comply with mandated performance requirements and comfort levels, but most importantly, to assist in realizing better patient outcomes.

Control temperature and relative humidity, and improve indoor air quality

- Optimize operating room environment for staff and patients

- Enhance quality level of air supplied to the OR air handler

- Precise RH control

- Consistent cooling

- Significant energy and utility savings experienced versus conventional systems due to the ability to utilize warmer chiller temperatures

The ability to simultaneously cool and dehumidify an air stream is unique to the Alfa Laval Kathabar technology. This translates into lowered operating costs and more efficient industrial dehumidification performance, while also utilizing the natural ability of Kathabar’s Kathene desiccant to help neutralize many pathogens that may be present in the outside air.

Documents

System benefits

Most cost efficient heat transfer technology

• Meets ASHRAE (American Society of Heating, Refrigeration and Air Conditioning Engineers) 170 OR temp/RH (relative humidity) requirement and surgical staff comfort

• Employs standard facility cooling and heating utilities

• Green technology, able to use waste heat for regeneration

• Minimal maintenance

• Highly effective industrial desiccant dehumidifier

• Kathene liquid desiccant neutralizes a number of known pathogens from incoming outside air

Exceptional Technology

The ability to simultaneously cool and dehumidify an airstream is unique to the Alfa Laval Kathabar technology. This translates into lowered operating costs and more efficient performance.

The Alfa Laval Kathabar liquid desiccant system (LDS) technology uses an absorbent solution - Kathene - which removes moisture from air as it moves through a conditioning spray chamber within the conditioner tower. Control of the space RH level from 20-60% at +/-1% is achieved.

Dilute solution collects within the system sump and is transferred to the regenerator where the moisture is removed. The concentrated solution is then transferred back to the conditioner.

Conversely, humidity may be added to the air stream by heating inlet air and providing deionized (DI) or reverse osmosis (RO) make-up water to the conditioner sump.

Robust, reliable system

Alfa Laval Kathabar LDS technology is engineered for reliable peak performance for the demanding environments in healthcare:

- OR

- SPD (sterile processing department)

- ICU

- Burn and Trauma

Kathabar LDS technology

The Kathabar LDS technology is the optimal method for maintaining any critical environment. Required temperature and RH levels and staff/patient comfort levels are all attained.

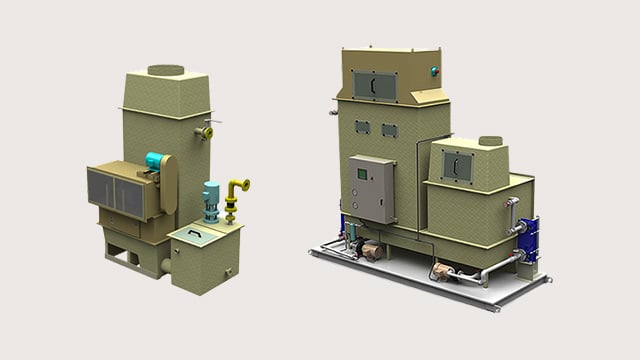

Regenerator

• Free standing pump and pump

tank assembly with sealless

fiberglass pump

• Housing of industrial grade fiberglass

construction with internal

parts of non-metallic engineered

plastics

• Integral fan/housing with inlet air

filtration

• Optional base platform with FRP

(fiberglass reinforced polyester)

clad construction

SP600 (Small Packaged)

• Self-contained conditioner and

regenerator into a single package

• All wiring, controls and solution

piping completed

• Standard base platform with FRP

clad construction

• Airflow to 7,500 CFM

• Conditioner and regenerator

fan/housings

• Horizontal end-suction conditioner

and regenerator pumps with

sealess magnetic coupled motors

FV600 (Conditioner)

• Airflow from to 7,500 CFM

• Integral fan/housing

• Free standing pump and pump

tank assembly with sealess

fiberglass pump

• Housing of industrial grade

fiberglass construction with

internal parts of non-metallic

engineered plastic

• Inlet air filtration plenum

• Integral solution filtration

• Optional packaged arrangement

with base platform of FRP clad

construction and all components

mounted, piped and wired

Unparalleled critical environment control

Alfa Laval Kathabar Dehumidification Systems provide precise control of demanding operating room conditions needed by surgical staff that both comply with mandated performance requirements and comfort levels, but most importantly, to realize best possible patient outcomes.

The Kathabar technology has many advantages over traditional HVAC systems:

• Ability to use existing facility CW (chilled water) system (42-48° F) to meet lower OR temperatures and required RH levels

• Lowers energy requirements

• Acts as a highly effective desiccant dehumidifier

Are your hospital’s lungs healthy?

In this podcast, Beyond Clean – the global voice for sterile processing, describes an HVAC system as the lungs of the hospital. But that same set of lungs, or HVAC system, is capable of allowing biofilms living inside, where it's the perfect moisture laden environment for dangerous microorganisms to thrive and be carried throughout the hospital.

In this candid podcast, Alfa Laval's Pat Leach discusses liquid desiccant dehumidification solutions and how they can help impact the quality of air entering the operating room environment.

Tune in now for the discussion:

A non-toxic solution for precise humidity control

Alfa Laval Kathabar liquid desiccant industrial dehumidification systems use Kathene, a non-toxic solution composed of lithium chloride salt and water, to absorb moisture from the air. Kathene does not vaporize and will not be degraded by common airborne contaminants. Kathene’s absorbency can be adjusted to create any relative humidity level between 18% and 80%.