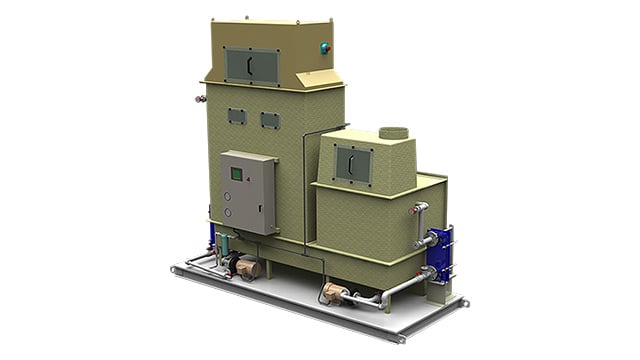

Kathabar SP

The SP series offers a high-efficiency, vertical airflow design in a factory-packaged, plug-and-play system. This system requires only the utilities at your plant and power to a single point. Ready-to-use SP units are ideal for small applications such as waterworks, casting applications, pharmaceutical drying rooms and filling areas.

Small, package conditioner/regenerator

- A combined conditioner and regenerator on a single skid for easy installation

- Vertical discharge, with available airflows ranging from 1,500 CFM to 20,000 CFM

- Industrial fiberglass (FRP) platform base with factory-mounted, desiccant solution pumps and heat exchangers

- Wiring, controls, and desiccant solution piping factory completed and tested

- Horizontal, end-suction desiccant solution pumps with seal-less, magnetically coupled motors

The SP liquid desiccant systems are designed for airflow capacities from 1500 CFM to 20,000 CFM.

The smaller SP sizes (SP240-600) are compact skid-mounted units with conditioner and regenerator towers that share a sump and offer our smallest footprint for a complete dehumidification system.

The larger SP sizes (SP800-1600) offer a FV conditioner of the same size paired with a FP 6 on one skid, with all components mounted, and the interconnecting desiccant solution piping and wiring completed at the factory.

Alfa Laval Kathabar SP

Components

A. Conditioner fan assembly and housing with eliminator access door

- For sizes 800-1600, there is a fan to tower adapter plenum with the eliminator access door

B. Industrial grade fiberglass housing

C. NEMA 3R Electric and control panel with PLC, HMI touchscreen, communications card for TCP/IP interface, fused disconnect

- Fan and pump motor starters for sizes 240-600

- Fan and pump VFDs for sizes 800-1600

D. Desiccant solution bypass filter with hand isolation valve

E. Conditioner and regenerator end-suction desiccant solution pumps with premium efficient motors, seal-less magnetic drives

F. Regenerator fan assembly and housing with eliminator access door

G. Regenerator plate and frame desiccant solution heater with titanium plates

H. Conditioner plate and frame desiccant solution cooler with titanium plates

I. All the above are factory packaged on a FRP platform base with complete electrical, control wiring and Kathene piping

Precise humidity control achieved with use of the below integral components:

- Air temperature and humidity sensor

- Coolant control valve with electronic actuator

- Heating control valve with electronic actuator

- Modulating desiccant solution transfer valves (only applicable to SP models 800-1600)

Real time performance monitoring and intelligent troubleshooting is obtained through the following elements:

- Spray temperature and pressure transmitters

- Desiccant flow verification meter (only applicable to SP models 800-1600)

- Guided wave radar digital desiccant level transmitter

- Conductive high-level switch

SP1600 skid ready for shipment

Related services

Our global service network has dedicated specialists, knowledgeable about the best solutions for your industry. We are here to support you with parts and expertise, wherever and whenever you need them.

The Alfa Laval 360° Service Portfolio covers all your needs throughout the life cycle of your equipment — from start-up, maintenance, support and improvements to monitoring services — for maximum uptime, availability and optimization.

By minimizing your total cost of ownership, we help you stay ahead of the competition.

Learn more about our service offering

Contact us

Do you have a temperature or humidity challenge? Alfa Laval has a flexible solution to help you solve it – simply and efficiently, with minimal stress and cost.