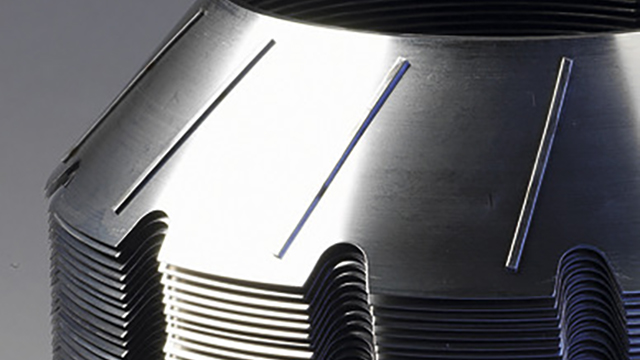

The centrifugal separator for metalworking fluids efficiently removes tramp oil, fine metal shavings and particles down to one micron resulting in reduced tool wear, fewer rejects, and an overall improvement in quality.

Secure long-lasting efficiency with tramp oil separator systems

Depending on your needs for cleaning of water-based metalworking fluids such as synthetic, semi-synthetic and soluble oils, Alfa Laval offers fixed and mobile solutions for smaller individual tanks with the Alfie 200 and Alfie 500. For larger and centralized tramp oil removal systems the AlfaPure series is the recommended solution.

Alfie 200

Centrifugal separator designed to remove tramp oil, grease and particle contaminants from water-based metalworking and wash fluids in tanks up to 1500 gallons.

-

Reduces fluid consumption

- Lowers disposal costs

- Improves both product quality and the work environment

- Allows for a bolt-on connection to the coolant tank

- Adapts automatically with an inlet bellows to the fluid level in the tank

- Provides sustainable fluid cleaning for single-tank operations

Alfie 500

Removes contaminating tramp oil, grease and solid particles from water base metalworking fluids and wash fluids in tanks up to 2500 gallons.

- Reduces fluid consumption

- Lowers disposal costs

- Improves both product quality and the work environment

- Complete compact tramp oil removal system, including centrifugal separator, feed pump and computerized control system

- Provides sustainable metalworking fluid cleaning for multi-tank operations

AlfaPure

Full range of centrifugal separator systems that removes tramp oil, grease and solid particles from metalworking fluids and wash liquids. For volume flows from 4 to 31 gallons per minute.

- Increases metalworking fluid life by up to 10 years

- Lowers disposal cost

- Reduces tool wear

- Provides for higher product quality and healthier work conditions

- Utilizes automatic particle (sludge) discharge

View more information about Alfa Pure S2 – up to 9 gallons per minute

View more information about Alfa Pure S3 – up to 13 gallons per minute

View more information about Alfa Pure S7 – up to 31 gallons per minute

The 4 most common cleaning methods for cutting fluids

Cutting fluids are an essential part of many machining processes, and without the right care and attention they become contaminated and can cause problems. By effectively cleaning your cutting fluids with a centrifugal separator, you can avoid these issues and reduce your overall operating costs. In this article, we explain the pros and cons of the different cleaning methods, and help determine which is best for your business.

Ditch the filters: 9 benefits of centrifugal separators

Cutting fluids get contaminated over time. While filters or replacing cutting fluids is an option many companies take, there are other opportunities that are cost-effective and efficient.

Why tramp oil is a chronic issue and what you can do about it

Learn why tramp oil and solid particles are a problem in metalworking and how you can clean your fluids and extend the life of your equipment while improving the working conditions for employees.

Service

An Alfa Laval centrifugal separator will perform for decades if you look after it properly. But you have to familiarize yourself with the manual and make sure you use genuine spare parts and the right tools. We provide specific service kits with genuine spare parts and a comprehensive package of detailed service instructions. We even have service videos on how to properly maintain your separator.

Let's talk!

Get ready to improve productivity and reduce equipment lifetime costs. Need help choosing the right solution? Contact us to learn more about how our metalworking fluids cleaning solutions can help your business. Simply complete the form and we'll get back to you as soon as possible.