Scraped surface heat exchangers

Scraped surface heat exchangers are essential for the continuous thermal processing of viscous, sticky, crystallizing, or heat-sensitive products. Designed for high efficiency and gentle handling, they ensure consistent product quality across demanding applications in the food, pharmaceutical, and personal care industries, delivering hygienic, reliable, and cost-effective performance.

Efficient thermal processing with Alfa Laval Contherm®

- More options: As the only range with both single and double-wall scraped-surface heat exchangers, there’s a Contherm® for nearly any application.

- More quality: Contherm® scraped surface heat exchangers are engineered to prevent fouling while preserving key flavour and nutritive components.

- More savings: With innovations for improved energy efficiency and minimal maintenance, Contherm® can ensure the lowest possible cost of ownership.

- More reliability: Every Contherm® is built with proven components, and backed by a global network with over 80 years’ experience in heat transfer.

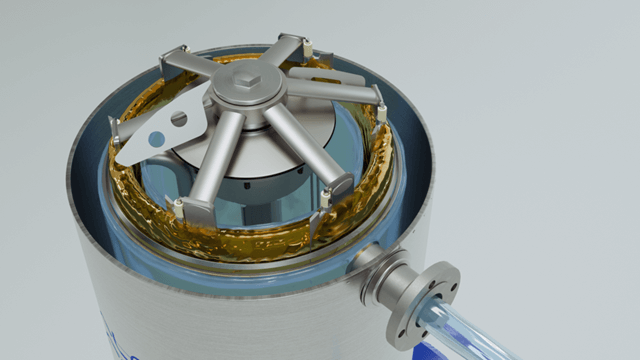

Contherm® scraped surface heat exchangers are robust, high-performance solutions for demanding heating and cooling duties across sectors such as food, pharmaceuticals, chemicals, and personal care. Unlike traditional heat exchangers, these systems are engineered to handle viscous, crystallizing, or particulate-rich materials, making them ideal for challenging applications.

Alfa Laval’s rotating scraping technology reduces fouling during operation, which maintains high thermal efficiency while ensuring gentle product handling. This is especially important for shear-sensitive or sticky formulations, where maintaining product integrity is critical. Compared to a static scraped heat exchanger, Contherm® provides a larger flow area and reduced pressure drop, maximizing uptime and process reliability.

Features that make the difference

Everything you need to meet your challenges

Efficient heat transfer for viscous food products

The Contherm® single-wall scraped surface heat exchanger is engineered to handle medium- to high-viscosity products while delivering high throughput and consistent thermal performance. Its mechanical flexibility and variety of heat transfer surfaces support a wide range of applications. The unit can be installed in vertical or horizontal configurations and is designed for easy maintenance, allowing seamless integration into diverse process environments.

Gentle product handling with optimized thermal efficiency

The tangential product ports and unique internal flow geometry ensure a gentle, low-shear process, protecting product texture and integrity. At the same time, the optimized combination of rotor diameters and scraper designs enhances thermal transfer efficiency while reducing product waste and operational costs.

CIP compatibility and Food Contact Compliance

Every Contherm® unit is CIP-suitable, ensuring maximum hygiene and efficient cleaning between production cycles. Alongside a wide selection of food-grade gaskets and contact materials, the system guarantees safe and sanitary operation, even under demanding processing conditions.

Hygienic stainless-steel design for demanding applications

With a hygienic stainless-steel build and high-quality surface finishing, the Contherm® portfolio meets strict industry standards for food safety and reliability. It supports critical processes such as heating, cooling, crystallization, and evaporation, making it ideal for processing complex and sensitive food products. All product-contact components are compliant with food safety regulations.

Flexible layouts for space-conscious process integration

A broad range of layout options—including single or double wall, and horizontal or vertical installation—makes it easy to adapt the Contherm® single-wall unit to your existing process line. This versatility supports footprint optimization and accommodates layout constraints in new or retrofitted systems.

Discover the complete Contherm® scraped surface portfolio

Contherm® scraped surface heat exchangers have long been trusted for processing viscous, sticky, and crystallizing products. Today, with the industry’s most complete scraped-surface lineup, Alfa Laval offers tailored solutions for nearly every production challenge.

As a global supplier, Alfa Laval is offering both single and double-wall scraped surface heat transfer systems. Contherm® at Alfa Laval stands out in versatility and innovation. Certain models are also engineered to handle extremely high product pressures.

Through close collaboration and process testing, Alfa Laval ensures that every unit is customized to meet specific customer requirements by providing optimized performance, durability, and product quality.

More possibilities across industries

The Contherm® portfolio of scraped surface heat exchangers in the food industry and beyond unlocks high-capacity, high-efficiency processing for demanding products. Traditional heat exchangers often fail when faced with viscous, particulate, sticky, or heat-sensitive ingredients, leading to product loss or inconsistent quality

Contherm® systems are engineered to handle these challenges with ease, offering reliable operation in both continuous and semi-continuous applications.

Beauty & hygiene formulations

Consumers expect consistent, high-quality health and beauty products. Contherm® technology ensures optimal results in:

- Body lotions

- Shampoos and conditioners

- Make-up products like mascara

- Toothpaste

- Deodorants

Food

Contherm® scraped-surface heat exchangers offer benefits in food applications where preserving valuable color, flavor and nutritive components is essential. Example duties include:

- Soups

- Sauces

- Dressings

- Fruit and vegetable purees

- Jellies

- Yogurt fruit

- Hummus

- Cream cheese

- Spreads

- Confectionary

- Protein such as meat & fish products, and ground meat product

Happy customers

Proven to give you more

Cedar's Mediterranean Foods is a leading manufacturer of hummus, with products in stores across the United States. Thanks to Contherm®, they can ensure a quality, all-natural product capable of surviving a long shelf-life without preservatives.

Related products

What is a scraped surface heat exchanger?

What is a scraped surface heat exchanger, and how does it differ from static designs? Unlike traditional models that risk fouling and thermal inefficiency with viscous or crystallizing materials, scraped surface heat exchangers use rotating blades to remove buildup from heat transfer surfaces continuously.

This ensures consistent heat exchange, improved hygiene, and higher process uptime, especially in the food industry where maintaining product integrity is key.

Why choose Contherm®?

With over 50 years of expertise, Alfa Laval is the only supplier to offer the full spectrum of scraped surface heat exchanger technologies. Contherm® systems are designed to meet evolving process needs, offering unmatched durability, hygiene, and performance.

Single wall or double wall scraped surface heat exchanger: Which Contherm® should I choose?

Choosing between a single-wall or double-wall system depends on your process conditions, product type, and capacity requirements. Alfa Laval helps customers identify the best scraped surface heat exchanger design by evaluating product behavior, temperature demands, and process goals.

Even more with Contherm® Max double wall heat exchanger

The Contherm® Max double-wall scraped surface heat exchanger boosts capacity for demanding applications while maintaining gentle, hygienic product treatment. This solution expands the Contherm® family to meet even more operational needs.