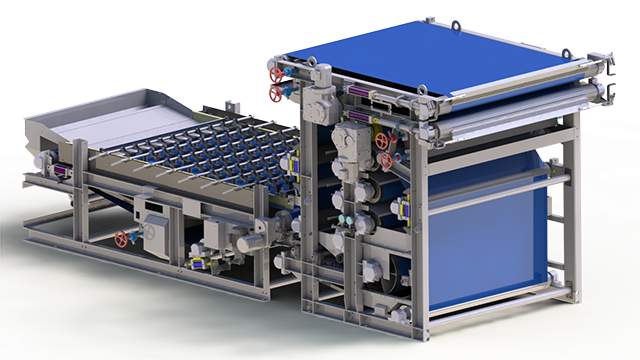

AS-H Belt Press KPZ

The Alfa Laval AS-H Belt Press KPZ is designed to handle high volumes of biosolids / residuals and deliver exceptional cake dryness. It is available in a number of configurations that can be customized to your wastewater sludge dewatering needs.

Unmatched wastewater sludge dewatering in a vertical belt press design

- High capacity design with low polymer consumption and low power usage

- Up to 70 PLI vertical pressure section, providing highest dry solids cake in class

- Independent, operator-level gravity deck and vertical pressure dewatering sections for maximum process control, especially if process conditions vary

- Low maintenance, long-life design that is flexible and easily upgraded as needs change

The Alfa Laval AS-H Belt Press KPZ is the next generation dewatering belt filter press designed to allow for high solids loading while maintaining a high hydraulic throughput. Performance results in exceptional sludge cake dryness in a layout that allows for an operator floor-level view of the gravity deck. It is suitable for all municipal biosolids and residual sludge types and a wide variety of industrial solid / liquid separation applications, such as paper, petrochemical, mineral, food processing, pharmaceutical and chemical. It incorporates variable energy mixing, flocculation, gravity drainage and pressure filtration. The design of the AS-H Belt Press KPZ allows for decreased civil construction costs, elevated cake discharge height, and low maintenance requirements.

Flexibility, performance, and easy inspection for operators

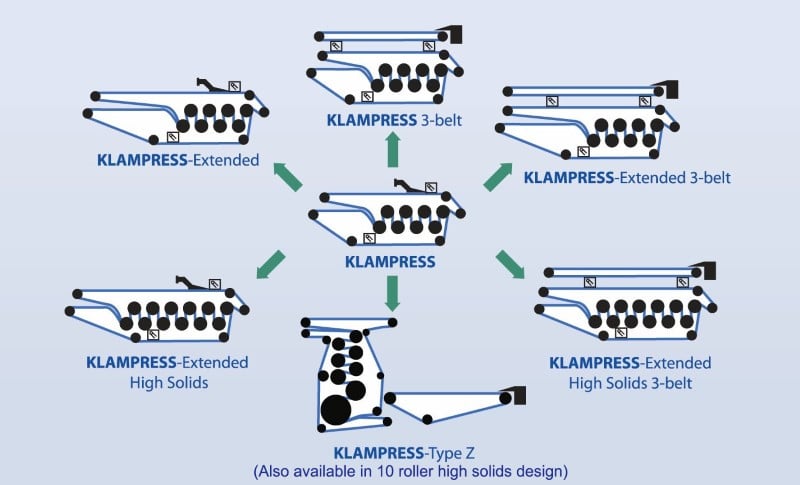

The Alfa Laval AS-H Belt Press range was developed by taking knowledge from decades of experience developed with traditional Ashbrook Simon-Hartley Klampress designs, and incorporating state of the art features and technology to deliver a portfolio of configurations to meet any sludge / residual dewatering application need.

Key strengths of the Alfa Laval AS-H Belt Press KPZ are the modular design and the vertical pressure section with low gravity deck.

Whether you have a low to moderate solids sludge and require the standard machine, or need the additional pressure rollers of a high solids design, the AS-H Belt Press KPZ can be configured to accommodate your process specifications. Modifications can easily be made in the future if conditions change, thanks to the modular nature of the machine.

Operators of belt filter presses will appreciate the low gravity deck of the AS-H Belt Press KPZ. This design allows for floor-level visibility of the gravity dewatering section without the need for stairs or platforms, meaning ease of process inspection.

How it works

The Alfa Laval AS-H Belt Press KPZ begins the dewatering process with a proprietary variable-orifice, in-line polymer mixer that combines polymer and slurry instantly, in less than one second. The product then begins to drain over an endless, horizontal porous filter belt. Next, the product moves to a vertical pressure section where it is gradually sandwiched by two additional belts in a series of decreasing diameter rollers. Finally, moisture removal is achieved by shear rollers arranged to give minimum 180 degree belt wrap at up to 70 PLI pressure in order to optimize dewatering.

The gravity and pressure dewatering sections of the AS-H Belt Press KPZ are independently driven, allowing for optimized process control.

Operator-specified belt tensioning is automatically maintained by a hydraulic belt tensioning and alignment system, which recognizes and corrects for subtle condition variations such as belt stretching or process changes. The arrangement of the AS-H Belt Press KPZ gravity drainage zone ensures even distribution of the conditioned slurry over the effective width of the moving filter belt.

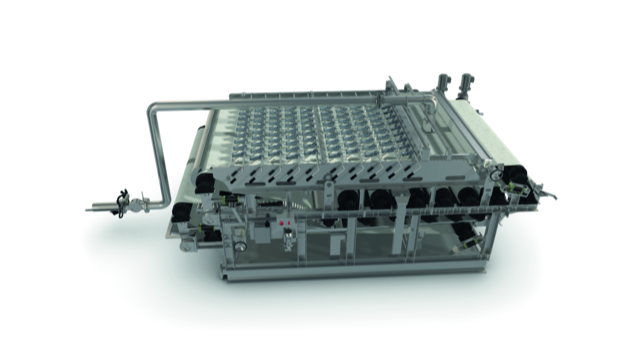

The AS-H Belt Press KPZ is equipped with lifetime-rated bearings, each protected by all stainless steel Fortress Bearing Housings™ with triple-labyrinth seals and shaft-mounted splash guards.

Unique features

Fortress Bearing Housing™

Impenetrable protection

Stainless steel construction with a triple labyrinth seal ensures no dust, water or other contaminants affect the roller bearing

Meeting your exact requirements

A variety of features and options make the high-capacity Alfa Laval AS-H Belt Press KPZ an excellent choice for your dewatering needs:

- Available in 8 or 10 pressure roller designs

- A variety of gravity deck lengths to match process requirements

- High performance advanced chicanes and high pressure vertical dewatering section ensure excellent performance under a variety of conditions

- Adjustable wedge dewatering zone allows for process optimization

- Lifetime rated bearings

- Radial grid and perforated roller to accelerate dewatering

A trusted partner, every step of the way

Alfa Laval's biosolids dewatering and thickening equipment is rooted in the rich history of Ashbrook Simon-Hartley. The knowledge and experience Alfa Laval has developed in these applications is unmatched and we will be here to help you achieve optimum process results. Thousands of installations around the world provides a database of knowledge on processes that ensures all options are considered when recommending equipment to solve your challenge.

Reviewing your process: Discuss the variety of technology options available and be confident in the final selection for your specific application. We’ll will work closely with you to ensure that the equipment you choose meets your current and future needs, and your process specifications.

Testing your Sludge (if needed): Test a sample of your sludge to determine the best technology and calculate process performance at our fully outfitted separations testing laboratory in Houston, TX.

Supporting your plan: Ensure success in the design, installation, and start-up of your equipment. From providing a budget quote, to discussing a complete turnkey installation, we will partner with you as needed every step of the way.

Servicing your equipment: Partner with our team to ensure that once your equipment is installed, it continues to reliably serve your application. Whether it is routine maintenance, or a complete overhaul or upgrade of a machine, our team of experts will be there to assist.

You may also be interested in:

Belt press designs for dewatering applications have gone largely unchanged over the decades. Find out what industry changes have required the design to adapt and how new innovations allow the belt press to remain a viable and effective solution for sludge dewatering.

10 top tips to keep your AS-H Belt Filter Press performing optimally

Have an Alfa Laval AS-H Belt press? Here are some top tips to help ensure that your equipment continues to perform at peak dewatering performance.

Solutions for the Circular Economy

More and more wastewater treatment plants are discovering the benefits of a circular, holistic approach to wastewater treatment. Cost savings, reduced environmental impact and new income streams from recovered resources are but a few. Every wastewater treatment plant is unique and has its own set of challenges and opportunities. With our expertise in processing and our broad range of products, we can support your shift to a circular resource flow. Regardless of whether you are a contractor, designer or plant operator we can help you find the optimum solution for your specific project.

How can we help?

With industry-leading wastewater technology and expertise based on the experience of thousands of installations, we can help analyze your unique situation and select the optimal equipment model, configuration, and services for your needs and budget. Get in touch by submitting a general inquiry using the contact form below.