Prepare for the future

Building a new plant or revamping an existing one is a big investment. It is essential to make the plant as future-proof as possible to maximize the return over time. Tougher environmental legislation, ability to expand capacity, labor costs and changes in feedstock and energy prices are a few factors to consider when entering the design phase.

Energy costs

Energy costs are a major part of most chemical producers’ budgets and energy prices are predicted to rise in the future. The difference in operating cost between two systems with differing energy consumption will most likely increase with time. This makes choosing equipment and process designs with low energy consumption crucial to staying competitive.

Evaporation systems

Evaporation systems are among the most energy intensive parts of a processing plant. Adding evaporation stages or effects, are an easy way to cut energy costs. For example, going from two to three effects can reduce steam consumption by as much as 35%. AlfaVap heat exchangers are specially designed for evaporation duties and their compact size makes it easy to add effects to existing systems without major reconstruction. Alfa Laval can help design the entire system for minimum installation and operating cost.

Decanter centrifuges

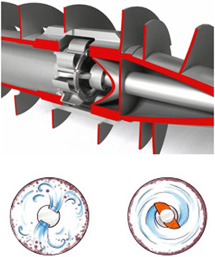

Alfa Laval decanter centrifuges feature a number of innovations that minimize electricity consumption. The patent-pending rotating feed zone available on some models reduces turbulence when the feed enters the decanter. This leads to improved separation, higher capacity and up to 40% lower power consumption.

The Power Plates liquids discharge directs the flow of the exiting liquid so that its kinetic energy helps drive the bowl. This reduces power consumption by 20-25% for 2-phase decanters and up to 40% for 3-phase decanters.

By combining a rotating feed zone with Power Plates, Alfa Laval’s engineers have managed to cut power consumption by more than 50%.

Membrane filtration

The viscosity of a stream passing through a membrane filtration system changes as various substances are separated out. Taking the flux curve and the viscosity profile into consideration when designing membrane systems allows us to choose the optimum channel design for different parts of the system, as well as to optimize the number of stages. This results in up to 25% lower power consumption.

Heat recovery

Recovering waste energy from one part of your plant and putting it to use in another is a well-proven way to battle energy costs. Heat can for example be recovered from overhead condensers or hot process streams and, depending on the energy content and the needs in the plant, it can be used in a number of ways:

- Preheating of process streams, evaporation system influents or boiler feed water

- Electricity generation

- District heating

- Providing energy for chiller systems

- Heat tracing

- Producing distilled water

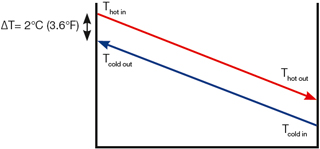

For maximum heat recovery, the heat exchangers must have a close temperature approach and operate with crossing temperatures. This means the cold stream is heated to a temperature very close to that of the incoming hot stream. A highly turbulent, counter-current flow lets Alfa Laval heat exchangers heat a cold stream to a temperature just 2°C (3.6°F) below that of the incoming hot stream (∆T= 2°C).

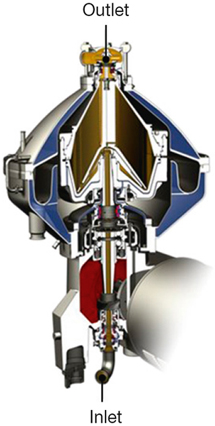

High-speed separators

Our unique, hermetic high-speed separators are the best choice for handling sheer-sensitive particles. They also offer up to 25% lower energy consumption than standard separators thanks to a special design with a hollow spindle inlet at the bottom of the bowl and a centrally located outlet at the top. Keeping both the inlet and the outlet at the center of the separator minimizes the forces where the liquids enter and leave the separator, and thereby the power consumption.

Environmental considerations

As the general public and governments around the world become increasingly more environmentally aware, legislation and requirements will likely increase.

Considerations include CO2 emissions, water consumption, handling of GMOs and waste and wastewater treatment to name a few things.

Alfa Laval offers a range of solutions that help chemicals producers minimize their environmental impact, for example by recovering energy, preventing the release of GMOs to the surroundings, reducing waste and lowering the amount of chemicals discharged to the environment.

Whitepaper: 10 ways to improve your bio-based chemical plant

The patent pending rotating feed zone reduces turbulence when the feed enters the decanter, resulting in improved separation, higher capacity and up to 40% lower power consumption.

The Power Plates liquid discharge can reduce power consumption by up to 40% by directing the flow of the exiting liquid so that its kinetic energy helps drive the bowl.

A close temperature approach and crossing temperatures maximizes heat recovery. An Alfa Laval heat exchanger can heat the cold stream to a temperature just 2°C (3.6°F) below that of the incoming hot stream.