Tank cleaning equipment and tank components

Efficient tank cleaning devices, tank accessories and more for your operation

Boost your productivity and your bottom line with Alfa Laval tank cleaning equipment and components. Whether you need sanitary or industrial tank cleaning solutions, tote washing, tank components, tank covers, tank feet or more, Alfa Laval application experts can guide you to the right solution or products for your operational process.

Enhance your tank cleaning system

Alfa Laval tank cleaning equipment safeguards your processing operations. Optimizing your cleaning cycles is just as important as optimizing production efficiency. Efficient tank cleaning is vital to eliminate cross-contamination, leading to improved quality, productivity and yields. We provide solutions for tanks, totes and vessels, regardless of shape, size or internal obstructions. With a wide range of industrial tank cleaning solutions to choose from, selecting the appropriate tank cleaning machine can result in significant savings in time, energy, water and cleaning materials, bringing you closer to your sustainability objectives.

All tank cleaning equipment

Rotary jet heads

Improve process efficiency, productivity and end-product quality with exceptional cleanability of your process tanks with Alfa Laval rotary jet head tank cleaning machines.

Rotary spray heads

The Alfa Laval rotary spray head tank cleaning machine is a free-rotating spinner that uses low volumes of cleaning media at low pressure for effective cleaning.

Wall mounted cleaning devices

Get improved cleaning coverage of tank shadow areas with the Alfa Laval wall mounted cleaning device.

Keep your tank cleaning device running at its peak

If you take proper care, your tank cleaning machine(s) will last for decades. We guarantee a 24- to 48-hour turnaround on all service and repairs so you don’t have to worry about excessive tank downtime.

Send repairs to:

Tank Cleaning Service Center

Alfa Laval

735 Fox Chase Road, Suite 108

Coatesville, PA 19320

Hours: 7:30 am to 5:00 pm EST, M-F

Save time and money

Safety, sustainability and cost savings are important objectives for your company, and tank cleaning automation can make a positive impact on all of them. Using the right tank cleaning system can significantly reduce downtime, while using fewer resources. Our devices are also designed to increase plant safety by eliminating confined space entry for manual tank cleaning.

Alfa Laval's rotary impingement tank cleaning devices are guaranteed to positively impact your bottom line. This patented technology saves companies all over the world billions of gallons of water and chemicals and facilitates massive increases in plant productivity and worker safety.

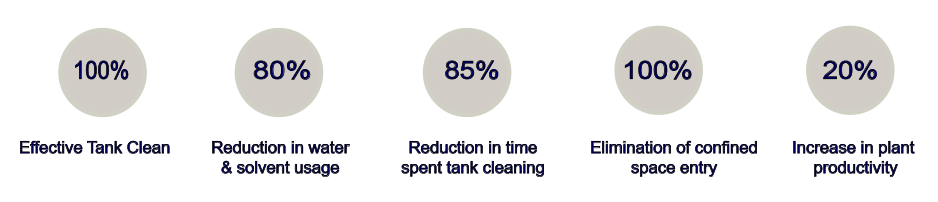

Our customers typically see benefits up to:

How it works

Rotary impingement tank cleaning

Clean tanks, IBC totes, ribbon mixers and blenders, kettles, dryers, reactors and more with our automated tank cleaning machines. Alfa Laval tank cleaning equipment combines pressure and flow to create high impact cleaning spray heads, spray balls, jet heads and more.

This precise, repeatable and reliable 360° jet pattern enables you to use the least amount of resources while achieving the most effective tank clean.

Optimize performance by choosing the right tank cleaning machine

Thorough tank cleaning increases productivity, maintains product quality and eliminates cross-contamination risks. Trust in Alfa Laval's broad process knowledge, tank cleaning expertise and deep understanding of cleaning challenges.

Improve hygienic processes with Alfa Laval tank equipment

Enhance process performance and product safety with Alfa Laval tank covers and accessories, complementing our portfolio of mixers, agitators and tank cleaning devices. Our tank components provide easy access to and from tank interiors, accurate pressure control, tank stability and a clear view of tank process conditions, product quality and cleaning status. From a sight glass with light fittings to a pressure relief valve or manway cover, Alfa Laval has reliable and effective tank covers and accessories for your process demands. Safeguard uptime by choosing the right tank equipment for reliable operation and savings in water, energy and cleaning media.

All tank components and accessories

Tank accessories

Let Alfa Laval tank accessories optimize the performance of your process tanks used in hygienic applications.

Tank covers

Keep your tank in top operating condition with Alfa Laval tank covers. Customize your manway covers for quick, easy and convenient entry and egress for inspection, cleaning or maintenance.