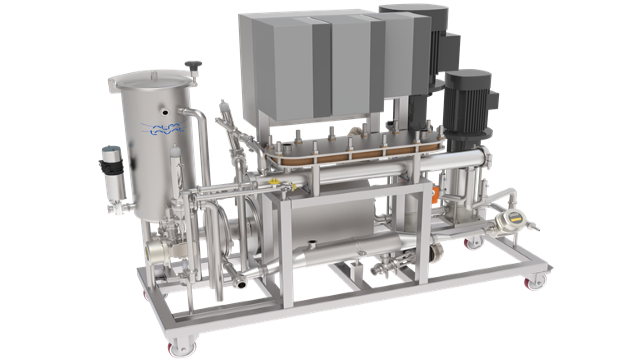

Lab/pilot units

The specific range of small-scale membrane filtration lab/pilot units for on-site testing provide you with data for evaluation of your membrane solution process feasibility, future design and scale-up. They can also be used to optimize existing processes or lines. Our breadth of membrane filtration equipment means that we can be with you from initial testing to full-scale production along the way. Benefit from our industry and application know-how, streamlined services and smooth transitions.

Market leading laboratory and pilot membrane filtration equipment for testwork

- Get correct answers to vital questions early on in development cycle

- Same design for both small-scale and industrial equipment allows seamless development of new processes and products

- Price-competitive solutions from source – Optimized design of your full-scale membrane system based on test results

- Process knowledge at hand – access to Alfa Laval Membrane and Application Development Test centre, experts and on site assistance

- In house development assures quality and rapid delivery times

Unmatched membrane technology and membrane filtration equipment

Optimum membrane filtration solutions normally derive from small-scale trials. That’s where you establish process feasibility, determine design data for up-scaling, optimize existing production lines or even carry out small-scale processing.

When it comes to membrane filtration processes, Alfa Laval is perfectly placed to help with those experiments. Our experience with membrane solutions dates back almost as far as the membrane technology itself and stretches across all the common types of filtration. Today we develop, manufacture, install and service membrane solutions and systems ourselves. So, with Alfa Laval, you tap into unmatched know-how and experience with membrane technology that comes with understanding every step of the process, and our people’s unique ability to address your needs at whatever stage of membrane filtration equipment development.

Read more about membrane filtration processes

Testing membrane technology at your site or at our pilot facilities

We provide small-scale modules, units and pilot plants for testing membrane filtration equipment and solutions on-site (rental or purchase) in connection with other process equipment. Our range of small-scale units and pilot plants is based on the unique plate-and-frame modules or the full-fit sanitary spiral elements or a combination of both. Sizes vary from only a few liters of test media volume in our LabUnits up to 1,000 liters in our PilotUnits.

We also do testing at our own state-of-the-art Membrane and Application Development Test Centre in Nakskov, Denmark. In both cases, we also provide highly skilled process consultancy services.