FEQX

The Alfa Laval FEQX nozzle bowl separators are designed for industrial fermentation applications and are available in many different sizes and configurations, each one designed and adapted for dealing with the widely varying separation tasks required.

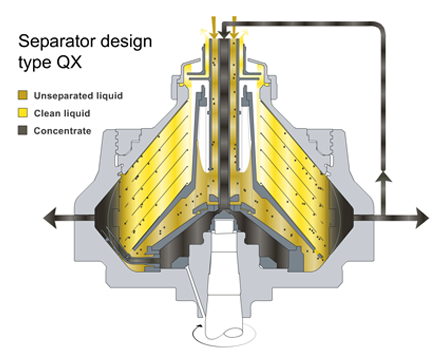

The FEQX separators are of the nozzle bowl type. The design makes them ideal for separating micro-organisms with high cell content and with or without solids impurities in the feed.

The FEQX separators also feature peripheral nozzles, but in addition it is designed to recirculate part of the concentrate through the nozzles to compensate for fluctuations in feed concentration and handle very low concentrations of feed solids.

How it works

The feed containing the liquid and the solids is introduced to the rotating centrifuge bowl from the top via a stationary inlet pipe, and is accelerated in a distributor before entering the disc stack. Separation takes place between the discs. The light phase moves through the disc stack towards the centre of the bowl, and is pumped out under pressure by means of a built-in paring disc. The yeast is collected at the bowl periphery and continuously discharged through the nozzles. Filler pieces prevent build-up of the solids between the nozzles.

The feed containing the liquid and the solids is introduced to the rotating centrifuge bowl from the top via a stationary inlet pipe, and is accelerated in a distributor before entering the disc stack. Separation takes place between the discs. The light phase moves through the disc stack towards the centre of the bowl, and is pumped out under pressure by means of a built-in paring disc. The yeast is collected at the bowl periphery and continuously discharged through the nozzles. Filler pieces prevent build-up of the solids between the nozzles.

Additional feature of the FEQX separator

A portion of the concentrated solids, discharged through the nozzles, can be recirculated into the bowl again through the recirculation inlet pipe, a separate distributor and the recirculation tubes.

Stay connected - Imagine the possibilities if you could have an eagle eye’s view of your equipment