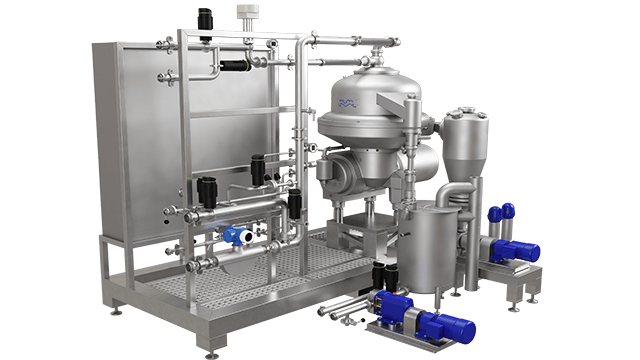

AFPX

AFPX separators are used in meat, fish and blood processing industries to purify and enhance recovery of valuable protein fractions, fats and oils. These robust and high performing separators are especially designed for extremely demanding separation duties in order to meet the tough requirements of the food industry and exceptionally high hygienic standards. With an AFPX separator from Alfa Laval, you can achieve exceptional, high-quality fats and oils with 99.7% purity.

For demanding separation duties in fish and meat industries

- Easy to operate and maintain

- Excellent wear and corrosion resistance

- Longer running times which ensures increased yield

- Cleaning in place (CIP) facility to keep the costs down

- Small footprint

Key features of the AFPX range of centrifuges are their ability to handle high flow rates, high solids content and high-temperature processing. These functions make it the ideal choice to handle the tough conditions encountered in the animal and fish processing industries.

Depending on duty and feed composition, the AFPX disc stack separator can be configured in three different executions: concentrator, purifier and skimmer.

In addition, the AFPX combines a high G-force, high sludge capabilities and automated operation.

Applications

The AFPX was designed to discharge solids intermittently, while at the same time separating two intermixed and mutually insoluble liquid phases of different densities. The centrifuges comes in a series of optimized executions that are suitable for a considerable number of duties, including separating fish press water, stick water and extracts. Other applications include the purification of fish oil and liver oil, animal fat, peel oil, and similar products.

AFPX protein separators range

AFPX 200 protein separator

- Easy to operate and maintain

- Robust and reliable

- Wear resistant

- Excellent corrosion resistance

- Low moisture content in fat

- Flexible installation options

- Small footprint

- Plug-and-play possible

AFPX 617 protein separator

- Easy to operate and maintain

- Robust and reliable

- Wear resistant

- Excellent corrosion resistance

- Low moisture content in fat

- Flexible installation options

- Large solids handling capacity

- Plug-and-play possible

How it works

Typical bowl drawing for a solids-ejecting centrifuge. Drawing details do not necessarily correspond to the centrifuge described

Separation takes place inside a rotating bowl. The feed is introduced to the rotating centrifuge bowl from the top via a stationary inlet pipe, and is accelerated in the distributor, before entering the disc stack. The distributor is designed especially to ensure smooth acceleration of the feed liquid.

The separation of liquid-liquid-solids takes place between the discs, with the oil phase moving through the disc stack to the centre and is discharged through pipes and sprayed out into the collecting frame. The water and solids separated from the oil moves out to the periphery, the water is led via channels in the top disc to the paring chamber, where it is pumped out of the rotor with means of a built-in paring disc.

The solids are collected in the periphery, from where it is discharged intermittently via the centrifuge cyclone. The solids discharge is achieved by a hydraulic system which at preset suitable intervals forces the sliding bowl bottom to drop down and thus opening the solids ports at the bowl periphery.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.