Package treatment plants

Package plants for biological wastewater treatment with activated sludge are a great way to achieve advanced wastewater treatment results in an economical manner. Alfa Laval package plants can be configured using a variety of processes and designed for either batch or continuous operation. This provides excellent flexibility in wastewater treatment options. Package plants of up to (approximately) 200,000 GPD for rectangular and 3 million GPD for field erected circular designs are available.

Tailored solutions for your wastewater process specifications

- Flexible configurations

- Process flexibility – Complete Mix-Activated Sludge, SBR, or MBR

- Continuous or batch process

- Process guarantees available

- Available in portable shop-fabricated rectangular, or circular field erected designs

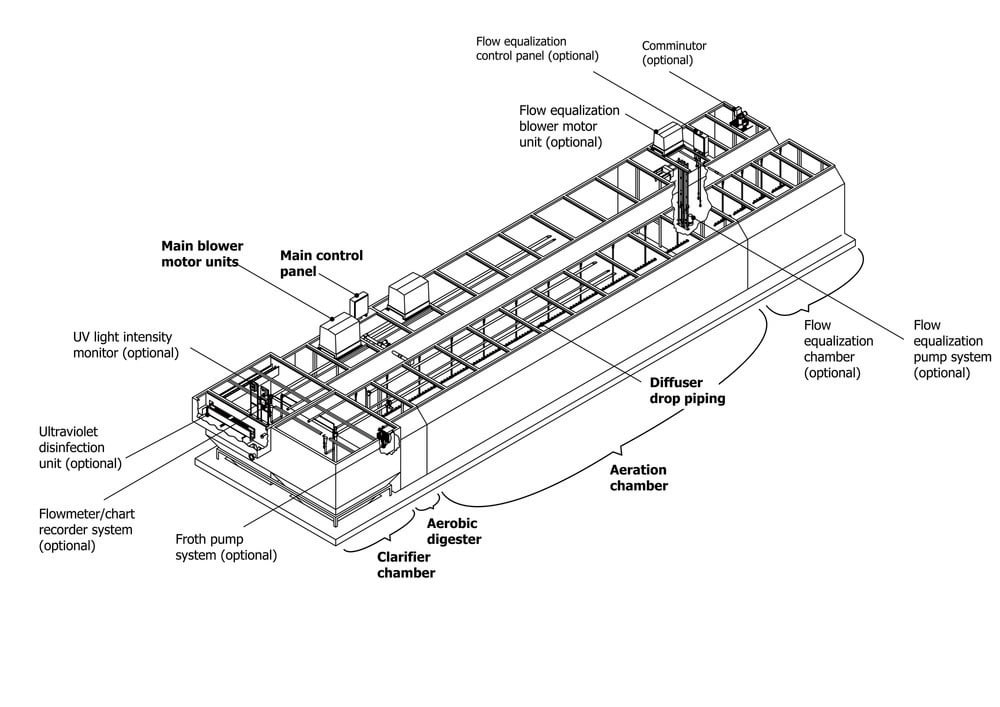

How it works

Alfa Laval AS-H Package Wastewater Treatment Plants are based on the activated sludge process that best meets the treatment objectives. They can accommodate both continuous flow and the sequencing batch reactor process. Whether it is the conventional pollutant removal or advanced treatment for biological nutrient removal (BNR) including nitrification, denitrification and phosphorus removal, the package plants are available with advanced effluent treatment capabilities. Each plant will be designed according to the site-specific needs.

Download the product leafltet

Technology

Construction Configurations

Package plants for activated sludge are available in a variety of configurations.

- Shop fabricated or field erected

- Above or below ground

- Constructed with capacities > 1 MGPD per train

Alfa Laval’s dedicated team will work with you to select the best configuration for your needs.

Choose from a broad range of technologies

Every wastewater stream is different, and every solution has benefits and trade-offs. Alfa Laval will provide you with the information and power to select what is right for your individual situation. Plants can be supplied with MBR, SBR, Extended Aeration or Complete Mix-Activated Sludge processes.

How can we help?

With industry-leading wastewater technology and expertise based on the experience from thousands of installations, we can help analyze your unique situation and select the optimal equipment model, configuration and services for your needs and budget. Get in touch by reaching out directly to the local contact for your area or submitting a general inquiry on the contact form.

Local contacts

East

Jaime Bengoechea

Regional Sales Manager - Process Systems

Email: jaime.bengoechea@alfalaval.com

Phone: (713) 816-0011

Coverage area: AL, CT, DC, DE, FL, GA, IA, IL (north), IN, MA, MD, MI, MN, NC, ND, NE, NH, NJ, NY, OH, PA, RI, SC, SD, VA, VT, WI, WV

West

Jaime Bengoechea

Regional Sales Manager - Process Systems

Email: jaime.bengoechea@alfalaval.com

Phone: (713) 816-0011

Coverage area: AK, AR, AZ, CA, CO, HI, ID, IL (south), KS, KY, LA, MO, MS, MT, NM, NV, , OK, OR, TN, TX, UT, WA, WY

You might also be interested in ...

Solutions for the Circular Economy

More and more wastewater treatment plants are discovering the benefits of a circular, holistic approach to wastewater treatment. Cost savings, reduced environmental impact and new income streams from recovered resources are but a few. Every wastewater treatment plant is unique and has its own set of challenges and opportunities. With our expertise in processing and our broad range of products, we can support your shift to a circular resource flow. Regardless of whether you are a contractor, designer or plant operator we can help you find the optimum solution for your specific project.

Reduce your environmental footprint and turn waste into value

All human, commercial and industrial activities produce waste products that are harmful to our environment unless treated. The world is therefore constantly on the look-out for ways to reduce pollution, provide clean water, use less energy and recycle energy already used. With growing populations and living standards plus water scarcity in many areas, there is also an increasing need for water reuse. See what you can gain from on-site water and waste treatment - and calculate your savings!