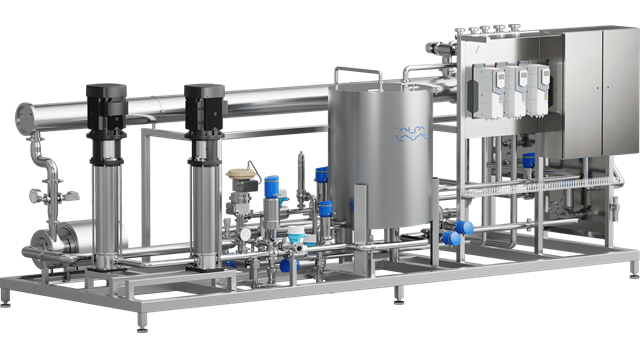

Low-alc de-alcoholization module

Achieve the full sensory experience of beer and fermented beverages with less than 0.5% ABV. The Alfa Laval Low-alc module helps you meet demand for healthier, low-alcohol alternatives without sacrificing quality. Compact and fully automated, it uses gentle, low-temperature membrane filtration to remove alcohol while preserving taste, aroma and mouthfeel. Energy-efficient and easy to integrate, it’s a smart, stand-alone solution for breweries, wineries and beverage producers.

Full sensory experience at less than 0.5% ABV

- Outstanding taste

- Scalable flexibility

- Cleaner waste stream through alcohol recovery and reuse

- Consistent quality in every batch due to spiral membrane filtration

- One system, endless product possibilities

Rely on the Alfa Laval Low-alc module to meet growing demand for healthier, great-tasting beverages with less than 0.5% ABV. Compact and scalable, it uses gentle reverse osmosis and spiral membranes to preserve the full product flavour, aroma, and mouthfeel.

One versatile module lets you produce premium low-alcohol beer, malt bases, ciders, wines, and other fermented beverages. Designed for flexibility, it adapts smoothly from craft to commercial scale, allowing you to adjust batch sizes and recipes as trends evolve.

The Low-alc module also supports your sustainability goals by reducing waste and generating new revenue through alcohol recovery. With low energy use, minimal oxygen pickup, and automated CIP, it’s a clean, efficient solution backed by Alfa Laval’s global support.

How the Low-alc de-alcoholization module works

The Alfa Laval Low-alc uses cross-flow spiral membrane filtration to gently reduce alcohol content while preserving the natural flavour and character of beer and fermented beverages. Operated at low temperature, it maintains product integrity throughout the process.

This skid-mounted, plug-and-play unit is designed for batch operation. It connects to a batch tank via an integrated swing-bend panel. Batch size and target alcohol levels are entered manually via HMI. Once started, the system runs automatically through the full cycle.

This de-alcoholization process using membrane filtration consists of three steps:

- Upconcentration – The beer or beverage is concentrated to approximately three times its original strength.

- Diafiltration – Deaerated water flushes alcohol from the concentrate, reducing the alcohol content to roughly three times the target ABV.

- Refilling – The system refills the batch tank with deaerated water to restore original volume and reach the desired alcohol level.

Achieving the final CO₂ level after processing requires carbonation.

Automated CIP is included, with manual dosing of cleaning agents and operator confirmation via HMI. The system is cost-efficient, easy to maintain, and extendable for future capacity needs.

Service

Food system services

Alfa Laval Food system services help extend the performance of your food systems by maximizing the performance of your processes. This enables you to:

- Continually improve your operations to maintain competitive advantage

- Focus on uptime, optimization and availability

- Maximize return on investment throughout the life cycle of your food systems

Be inspired

There is a steady, substantial and global move towards beers featuring less alcohol. Some brewery experts reckon that by 2020 as much as 20% of all the beer sold will fall into the so-called “healthy” category. For “healthy”, read “with alcohol content removed”. But how can one use the removed alcohol?