Marine refrigeration

Refrigerants are common in the marine industry, from chilling/freezing catch on fishing vessels to air conditioning on cruise ships or ferries. Yet traditional CFC and HCFC refrigerants have given way to HFC, and shipowners are exploring natural refrigerants like CO2. Alfa Laval has the advanced marine refrigeration systems, heat exchanger solutions and expertise to support natural refrigerant choices onboard food transports, gas/LPG carriers and more.

Sustainable marine refrigeration transition

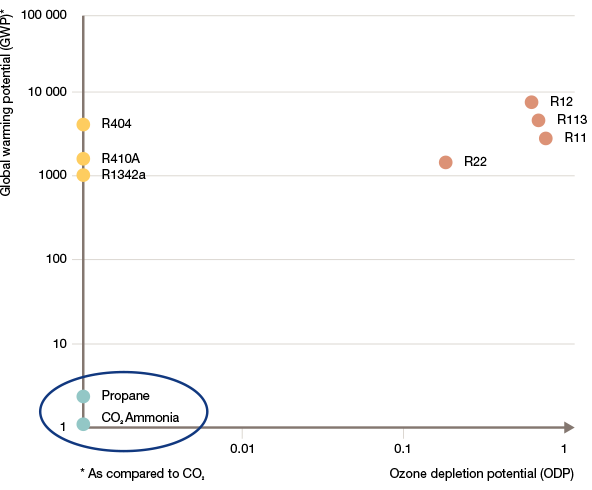

The move to more environmentally friendly marine refrigeration began with the ban on ozone-depleting chlorofluorocarbon (CFC) refrigerants. Today, 70% of the refrigerant in the merchant fleet – and especially on fishing vessels – is R22. R22 is a hydrochlorofluorocarbon (HCFC) with much lower ozone depletion potential (ODP), but its global warming potential (GWP) remains extreme.

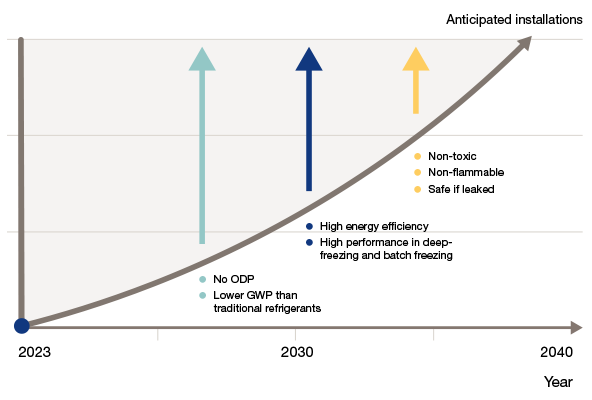

Now the industry is moving away from traditional options like R22, which has been forbidden as a refill refrigerant in Europe since 2015. The trend is towards natural refrigerants like ammonia (R717), propane (R290) and CO2 (R744), which have no ODP and a far lower GWP. The release of refrigerants from shipping is currently estimated at 8400 tonnes per year, which corresponds to around 2% of the industry’s greenhouse gas emissions (GHG).

CO2 as a marine refrigerant

Natural and increasingly economical options like ammonia, propane and CO2 can be used as refrigerants with high energy efficiency. CO2 requires robust heat exchangers that can work safely at higher pressures.

Heat exchangers for CO2 as refrigerant

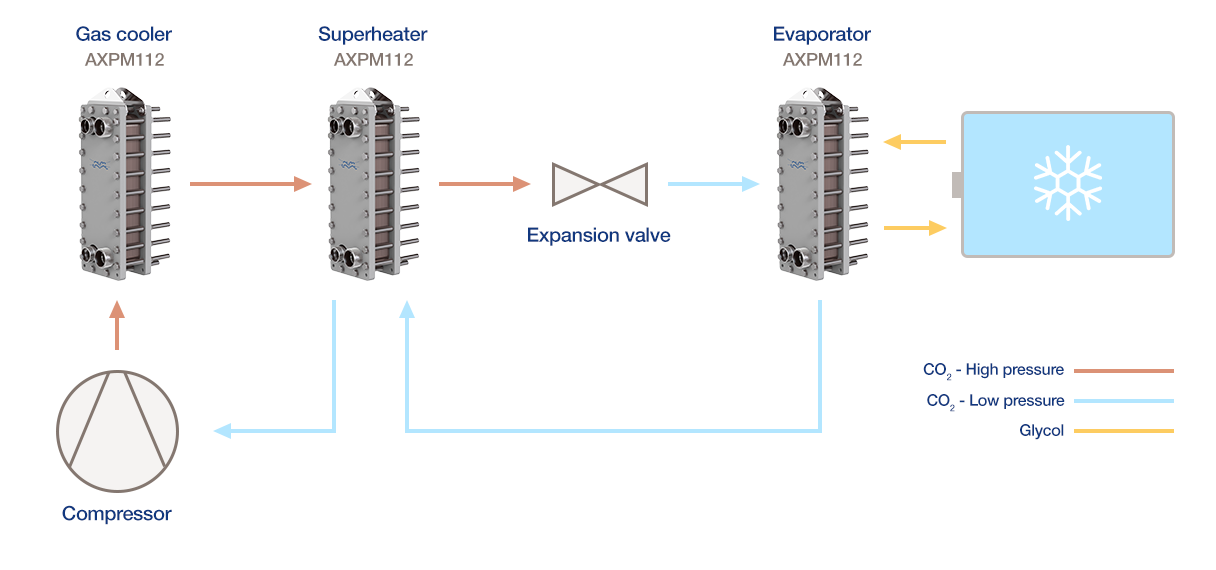

When using CO2 as the refrigerant, high pressures of 100-110 bar are required within the refrigeration system. This makes the copper-brazed Alfa Laval AXPM112 heat exchanger an ideal choice for safety. Part of the Alfa Laval AXPM line, the AXPM112 has exceptional pressure performance and efficiency due to its reinforced copper-brazed technology. Its high thermal performance results in lower operational cost, and its small hold-up volume means a lower investment cost for refrigerant. When retrofitting/upgrading, the AXPM112 is an optimal solution due to its small footprint.

Energy efficient solutions

Ideal as evaporators and condensers for onboard refrigeration systems, Alfa Laval semi-welded plate heat exchangers are the smallest, lightest, most efficient cooling units on the market. Our brazed plate heat exchangers are designed and fully optimized for onboard air-conditioning and refrigeration duties. When seawater is utilized, our range of marine shell-and-tube condensers are the ideal solution. Alfa Laval brine air unit coolers are the energy efficient choice for cargo refrigeration systems onboard reefers and other vessels.

AXPM

Alfa Laval AXPM stands for “extreme pressure,” and that’s exactly what these brazed plate heat exchangers are designed to handle. Specifically engineered for subcritical and transcritical applications using CO2 (R744) as a refrigerant, the AXPM line can also support other fluids that require very high pressures. AXPM units are suitable for duties ranging from heat recovery, condensing and sub-cooling to gas cooling, suction gas heating and more.