Biopolymer production

Renewable materials used to produce chemicals, fuels and plastics are on the rise as we move away from fossil feedstocks. In the transition to a circular economy, chemicals and materials produced from biomass will play a key role. Biobased chemicals, fuels and plastic production is expected to grow.

Biopolymers are plastic materials produced by industrial fermentation from renewable biomass sources instead of fossil fuels. In the race to reach our collective sustainability goals, biopolymers are being used as a more circular solution to conventional petroleum plastics. While the technology has been available to us for over 100 years, biopolymer production has been growing in popularity since recent EU directives aimed at reducing single-use plastic .

Robust, proven technology for biobased processes

Biomass processing requires separation steps that Alfa Laval can provide. Listen to our applications expert discussing how Alfa Laval through mechanical and thermal separation can help separate products in several steps of the production of biopolymers, and to recycle the water used in the washing stages.

Two main types of biopolymers

There are two main types of biopolymers showing potential in the industry. The most frequently used is PLA, or polylactic acid. This is made by extracting sugar from plants like sugarcane and field corn and is often seen in plastic bottles, utensils, and textiles. The alternative production is PHA, or polyhydroxyalkanoates. This can be used in a broader range of applications.

PHA

PHA is produced by fermenting natural raw material such as sugar or lipids. First, bacteria are fermented to grow a biopolymer within their casing. Once the desired yield is reached, the bacteria are harvested from the fermentation broth to increase the concentration. The biopolymer is then extracted from the bacteria cell, which can be done physically or chemically depending on each production specifications. Finally, the lysate is extracted to form the biopolymer. PHA is often more adaptable and less elastic than other plastics, making it a much more versatile option to produce.

PLA

Unlike PHA plastic, PLA biopolymers is not produced within the bacteria cell. Instead, it is synthesised using a different fermentation and separation method. The bacteria act as a catalyst during the fermentation process before it is separated from the main water solution. The lactose acid found in this solution is then polymerized to form the finished product.

Product overview

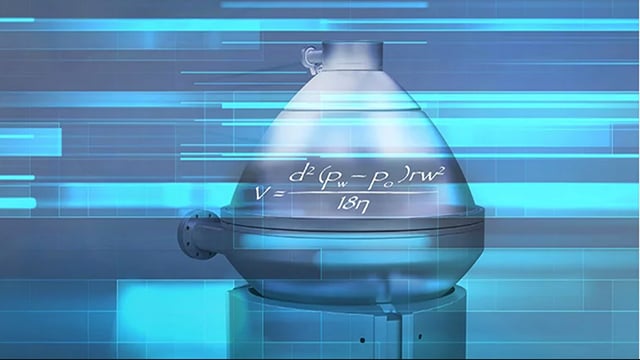

Disc stack separators

When we need to separate liquids with a lower concentration of solids and smaller particle sizes, centrifugal force can be used to get a more effective result. Our centrifugal separators use disk stack technology to separate even liquid from liquid, ideal for the small bacteria found in the biopolymer production process

Increase your separation efficiency and reduce energy consumption in completely enclosed operation

With the help of Alfa Laval’s patented hermetic design, the bacteria will not break before the harvesting phase. Our unique design is specified to this type of process, guaranteeing a more efficient, higher yield with 40% less power used. This design can be found in both PLA and PHA production, depending on if you are using our Clara or PurePulp centrifugal separators.

Clara

With the help of our Clara separator series, we can help you optimize your biomass removal and separation process. The Clara separators are well known to cover a broad range of clarification tasks and are ideal for the industrial fermentation required in both PLA and PHA biopolymer production.

Bactofuge/PurePulp

Our Bactofuge separator is ideal for the initial stages of the PHA production process, as it creates the perfect conditions to continuously discharge bacteria, without breaking the cells. In fact, the Alfa Laval PX 810 Bactofuge is created specifically for removing microbial cells from broths like those found in PHA production. The continuous solid discharge design can handle high volume cell loads and provide more efficient separation.

Late, during the lysis process, the bacteria cell is broken to extract biopolymers using the help of the aforementioned Clara separator range, or the FESX separator.

Zero Liquid Discharge

Biopolymer production requires a substantial amount of water due to several washing stages. Normally this water is managed in a regular wastewater treatment system, but with the help of Alfa Laval’s zero liquid discharge technology, this water doesn’t have to go to waste. Instead, it can be cleaned, recycled, and reused to improve production efficiency and your carbon footprint. Our water and waste treatment solutions will reduce your carbon footprint from wastewater streams. Plus, we have years of expert experience in separation and thermal technologies for these types of applications.

Optimize water recovery for re-use by combining an Alfa Laval decanter with one of our plate evaporators. Each system can be adapted to the specific separation duty and capacity of any production. So, you can maximize water use and minimize energy consumption by turning waste to value.

Gasketed plate-and-frame heat exchangers

Alfa Laval’s heat exchanger products can help you thermally control your process in the most energy efficient way. Benefits of Alfa Laval’s wide range of gasketed plate-and-frame heat exchangers are: easy to clean, flexible design allows customized designs, allows tight pinch point and crossing temperatures, compact size to minimize installation space requirement. Within the production of biopolymers, our gasketed plate-and-frame heat exchangers can be used for feed heat treatment, condensation, pre-heating and cooling.

Welded spiral heat exchangers

Alfa Laval spiral heat exchangers are designed to handle the toughest heat transfer challenges. Whether it’s frequent fouling from dirty media, or limitations from pressure drop and floor space, they are the ultimate problem solver for liquid-to-liquid and two-phase duties. The robust, efficient and compact designs keep both installation and maintenance costs extremely low, and they have a proven reputation for almost never fouling up.

Proven technology for biobased processes

The use of biobased processes in the Chemicals, Pulp and Paper, and Renewable/Recycling industries is growing. Disc stack separators are since long a key technology in, for example, industrial fermentation and algae processes in food and pharma industries. Our separation equipment and know-how are invaluable for these new process industries.

Alfa Laval center-to-center design

Learn about the inner workings of the center-to-center function which provides a hermetic design and an enclosed process. See how it provides gentle product handling and maximum product quality

Case story: Hear from one of BASF's plant manager

Efficient separation of biomass with Alfa Laval hermetic technology.

Do you want to explore your separation challenge further by yourself?

Try it out on your own with our easy-to-use Explore tool, or reach out to us for guidance.

Manufacturing world-leading separators

Alfa Laval delivers premium products for energy, food, water, biotech and pharma applications across the world based on more than a century of experience. Here’s one example from our Eskilstuna factory in Sweden.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.

Contact us

If you are looking for superior separation performance, contact Alfa Laval today to learn more about our robust and cost efficient solutions.