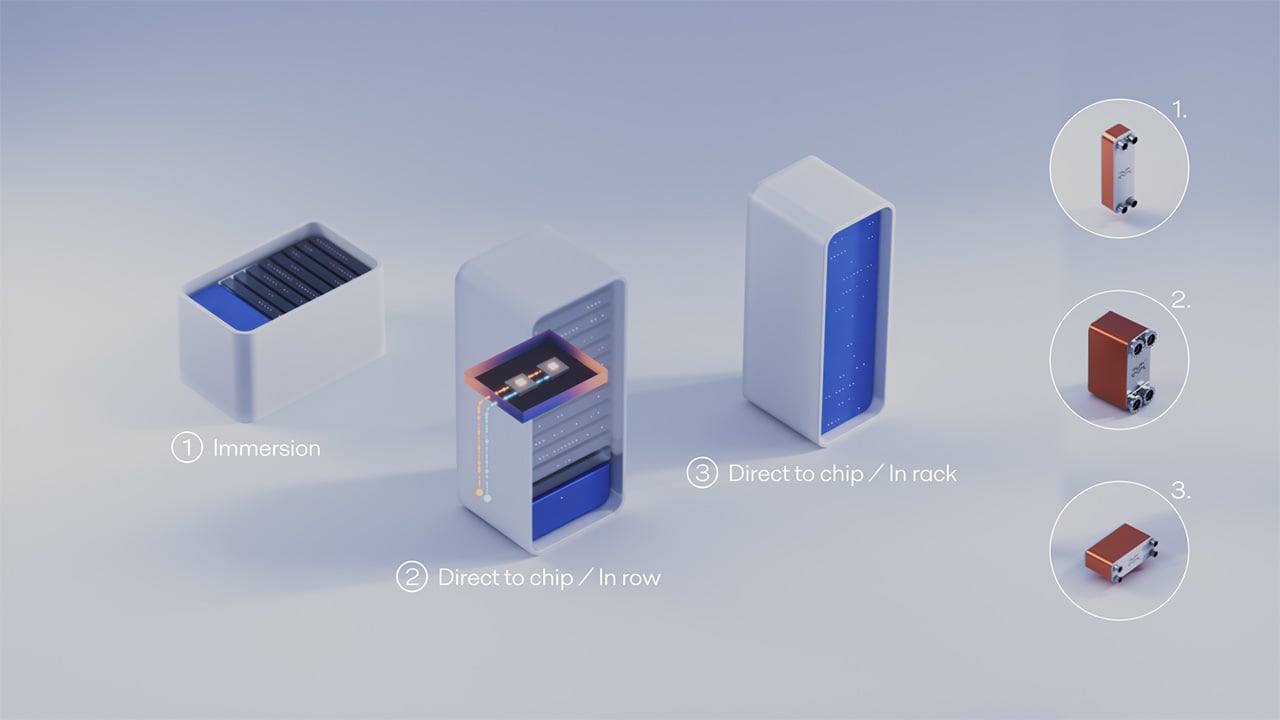

Direct-to-chip cooling for high-performing data centers

When AI pushes processors to their limit, direct-to-chip liquid cooling delivers precise thermal control right where it counts.

The ultimate protection for CPUs and GPUs starts with cooling at the core. With direct-to-chip cooling, you can:

- Enable higher density servers

- Build capacity for AI and machine learning

- Save on operating costs

- Extend the lifespan of hardware with reduced thermal stress

- Unlock opportunities for heat reuse

- Lower PUE (Power Usage Effectiveness) and CUE (Carbon Usage Effectiveness)

Thermal management at the chip level

Direct-to-chip cooling works by circulating fluid through cold plates that sit directly on top of CPUs and GPUs. These plates pull heat away right at the source. The coolant then carries the heat to a Coolant Distribution Unit (CDU), keeping processors cool and systems reliable.

Comparing single-phase and two-phase direct-to-chip cooling

Single-phase direct-to-chip cooling

Coolant absorbs heat from the processor and returns to the CDU as a liquid to be cooled and recirculated.

- Moves heat away as liquid

- Handles moderate to high thermal loads

- Simplifies design and operation

Two-phase direct-to-chip cooling

Coolant changes from liquid to vapor as it absorbs heat, then condenses back to liquid at the CDU.

- Removes heat through phase change

- Manages extreme AI and HPC thermal loads

- Increases efficiency in dense racks

A competitive edge that starts with smarter cooling

Why do the best data centers trust Alfa Laval? Because we help them turn cooling into a strategic advantage.

With 140 years of innovation and millions of heat exchangers installed worldwide, our solutions are proven to cut energy costs and improve system reliability for critical IT infrastructure. With a global manufacturing footprint, scalable supply chain, and expert support at every step, our mission is to empower data centers with a strategic advantage for tomorrow.