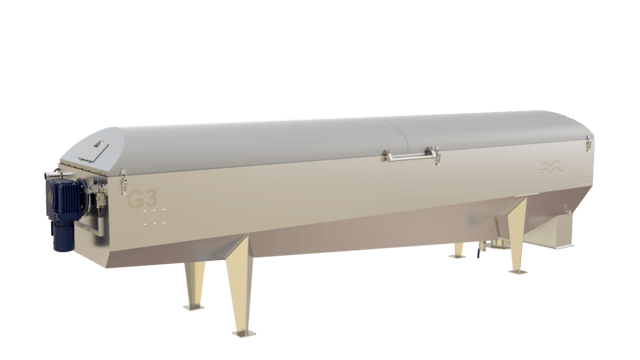

ALDRUM G3

The Alfa Laval ALDRUM G3 rotary drum thickener sets a new standard for sludge thickening. Its enhanced design improves process performance while minimizing operating costs.

Performance made simple

- Greater capacity with a compact footprint

- Low polymer consumption, ensuring low operating costs

- Outdoor installation possible, if required

- Enclosed design for a clean, low-odor working environment

- Simple maintenance with cleaning-in-place system that uses potable water, final effluent or treated filtrate

How it works

The ALDRUM drum thickener works on the principle of conveying polyelectrolyte treated sludge (a.k.a. flocculated sludge) through a slowly rotating drum filter. The sludge remains in the drum, while the water phase passes through the filter cloth.

The ALDRUM can be adjusted to suit individual sludge thickening needs. It is possible to achieve the most efficient thickening by varying the feed rate, the polymer type and dosage, the drum speed, and the spraying interval. The most cost-effective flocculation and polymer dosage is achieved by installing a flocculation reactor and/or mixing valve upstream of the actual drum thickener.

The ALDRUM can be used in industrial (such as pulp and paper) or municipal wastewater sludge thickening applications prior to digestion or dewatering, and for reducing sludge volume prior to storage or transportation.

Meeting your exact requirements

A selection of auxiliary equipment is available for the complete ALDRUM range:

- Mixing valve: Ensures thorough mixing of polymer and sludge. Can be installed directly on to the drum thickener inlet or before the flocculation reactor

- Flocculation reactor: Simple open reactor that kick-starts the creation of large and strong flocks. Can be installed directly onto the drum thickener inlet

- Sludge hopper: Leads the thickened sludge to the sludge pump in a controlled and efficient manner

- Control panel: All-in-one control solution. Control of the plant’s feed pump, sludge pump and polymer pump, as well as the drum thickener, the level in the flocculation reactor and the sludge hopper

Case story

Recycled paper producer uses Alfa Laval's ALDRUM to cut sludge dewatering costs

Dalum Papir A/S is one of the world’s leading manufacturers of 100% recycled, high-quality paper for the graphics industry.

You may also be interested in:

Lab and pilot testing for municipal and industrial water and wastewater

Alfa Laval has a full testing lab to determine the best solution for achieving the sludge thickening and dewatering results you need. Pilot testing also available.

Solutions for the Circular Economy

More and more wastewater treatment plants are discovering the benefits of a circular, holistic approach to wastewater treatment. Cost savings, reduced environmental impact and new income streams from recovered resources are but a few. Every wastewater treatment plant is unique and has its own set of challenges and opportunities. With our expertise in processing and our broad range of products, we can support your shift to a circular resource flow. Regardless of whether you are a contractor, designer or plant operator we can help you find the optimum solution for your specific project.

How can we help?

With industry-leading wastewater technology and expertise based on the experience from thousands of installations, we can help analyze your unique situation and select the optimal equipment model, configuration and services for your needs and budget. Get in touch by reaching out directly to the local contact for your area or submitting a general inquiry on the contact form.

Request a quote

Submit your process information to receive an estimated price range for this application. (Please note that this will be a budget estimate only. A firm quotation will require more detailed process parameters.)

Local contacts

Midwest

Chuck Shaw

Regional Sales Manager – Water Separation Sales – Midwest

Email: chuck.shaw@alfalaval.com

Phone: (317) 345-5512

Coverage area: IA, IL, IN, KS, KY, MI, MN, MO, ND, NE, OH, SD, TN, WI

Northeast

Jose Carpio

Director of Sales – Water & Wastewater

Email: jose.carpio@alfalaval.com

Phone: (804) 852-9340

Coverage Area: CT, DE, MA, MD, ME, NH, NJ, NY, PA, RI, VT, WV

Northwest

Roger McKinney

Regional Sales Manager – Water Separation Sales – Northwest

Email: roger.mckinney@alfalaval.com

Phone: (559) 317-8551

Coverage area: WA, OR, ID, MT, WY, CO, NM

South

Marc Arquit

Regional Sales Manager – Water Separation Sales – South

Email: marc.arquit@alfalaval.com

Phone: (713) 882-1286

Coverage area: AR, LA, MS, TX, OK

Southeast

Mark Schlitzkus

Regional Sales Manager – Water Separation Sales – Southeast

Email: mark.schlitzkus@alfalaval.com

Phone: (713) 906-0505

Coverage area: AL, DC, FL, GA, NC, SC, VA

Southwest

Marc Perratore

Regional Sales Manager – Water Separation Sales – Southwest

Email: marc.perratore@alfalaval.com

Phone: (201) 388-8393

Coverage area: CA, NV, AZ, UT