Raising the bar to protect groundwater in China

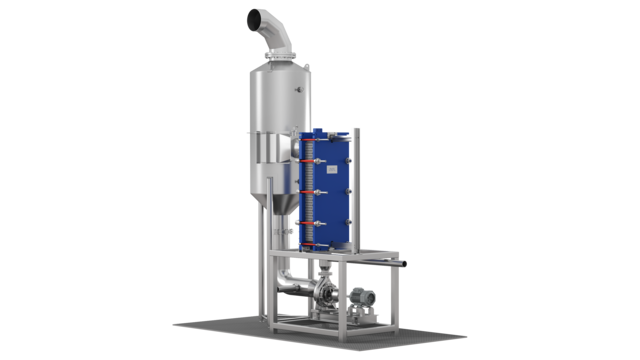

AlfaFlash evaporation technology is proving to be a game-changer for water conservation for a system builder in China specializing in the treatment of leachate – the water that comes into contact with the waste stored in a landfill.

DATE 2024-03-26

Xiamen Jiarong Technology Co., Ltd is a leader in landfill leachate decontamination in China and one of Alfa Laval’s business partners – removing suspended solids and harmful impurities, such as PFOS, nitrogen and heavy metals, from the leachate in a process that is strictly regulated to prevent groundwater and environmental pollution.

The company provides turnkey solutions and services for municipalities across China. Unhappy with the results from conventional existing shell-and-tube evaporation system, the company approached Alfa Laval to develop a solution.

Sales Manager Nick Wei believed the answer lay in Alfa Laval’s AlfaFlash technology despite no established reference in this application.

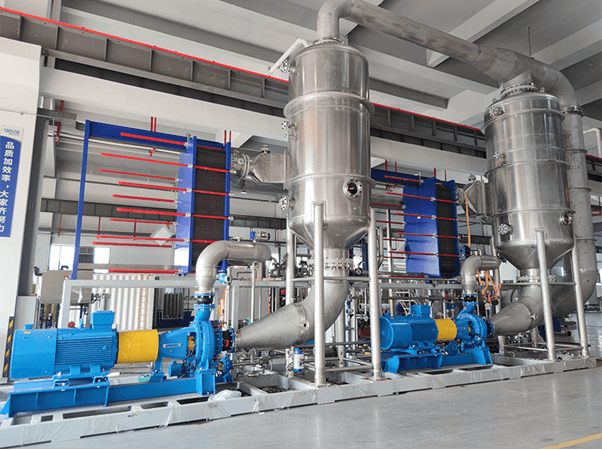

Strong cooperation and a high level of confidence in competences between the two companies, based on long experience with Alfa Laval’s membrane technology, meant that Jiarong was willing to install AlfaFlash in a turnkey landfill leachate treatment project at a site in China’s third biggest city, Chongqing. The processing scale of the project treatment is 1,000 tonnes/day in the early stage and about 500 tonnes/day in the later stage (after the completion of the existing stock treatment).

“Initially, they regarded this as a pilot project,” Nick explains. “Commissioning took place in March this year, and after a month, they rang me and said the performance was far beyond their expectations. So, they agreed to purchase 10 sets of the AlfaFlash system within two years.”

The AlfaFlash technology is one step in a process that utilizes ultra-filtration, reverse osmosis, decanter separation, and/or vacuum drying. At the end of the entire process, the liquid condensate is of high enough quality to either be reused or released into the environment while a specialist contractor for safe disposal removes the residual dry solids.

“Our technology saves the customer a lot of time and money,” Nick says. “Compared to the competitor, the quality of the condensate is cleaner and easier to handle. According to the test data provided by Jiarong, the condensate generated by the AlfaFlash evaporation system has about 4 times fewer pollutants than when using competitor equipment, and it is easy to meet the national emission standards through subsequent advanced treatment.”

And there are several other benefits. For example, the evaporator can run for up to 20 days before cleaning, whereas the previous shell-and-tube evaporators needed to be cleaned every two to three days. It also requires fewer chemicals upstream in the process, reducing both the environmental impact and the operating cost.”

“Our takeaway from this cooperation is that the AlfaFlash evaporator technology in this application is well-suited for the treatment of leachate at other landfills,” Nick says.

According to a company spokesperson at Jiarong, there are more than 1,700 large and small landfills nationwide in China. However, since 2003 the Chinese government has restricted the increase in landfills while supporting the development of incineration plants. Therefore, since 2003 new landfills have been few and far between, and the proportion of incineration plants has risen. As a result, the amount of waste processed by waste incineration plants should have exceeded the amount of waste in landfills – especially considering that many landfills have entered a closure period, which means that the overall leachate production is decreasing yearly.

With the end of Covid-related lockdowns, Jiarong feels confident in the continued growth of its business and is actively promoting the AlfaFlash evaporation system to other similar applications.

Download the case story

Highlighted technologies

Preservation of groundwater

The processing scale of the project treatment is 1,000 tonnes/day in the early stage and about 500 tonnes/day in the later stage (after the completion of the existing stock treatment).

The removal of contaminants

|

Chemical |

Measure |

Feedstock |

Condensate |

|

Calcium (Ca2+) |

mg/l |

464 |

|

|

Magnesium (Mg2+) |

mg/l |

976 |

|

|

Chloride (Cl-) |

mg/l |

27,253 |

|

|

Sulphate (SO42-) |

mg/l |

32,040 |

|

|

Silica (SiO2) |

mg/l |

59.9 |

|

|

Total Dissolved Solids (TDS) |

mg/l |

73,230 |

|

|

Conductivity |

µS/cm |

99,400 |

195 |

|

Chemical Oxygen Demand |

mg/l |

3169 |

554 |

|

Ammoniacal nitrogen (NH3/NH4) |

mg/l |

5,423 |

86 |

|

pH |

S.U. |

6.24 |

9.72 |

Technology shift

From conventional existing shell-and-tube evaporation system to Alfa Laval’s AlfaFlash evaporators.

Open landfills are common in most parts of the world outside Western EU countries and have long been a major concern due to the hazards and impact on the environment, health and livelihood of people and animals. In India, most landfill sites are typically dumping grounds in low-lying areas where waste is used to fill them – hence the name “landfill”. Landfills typically lead to excessive groundwater pollution, methane gas emissions and fire hazards (Source: UN Habitat). According to www.atlas.d-waste.com, there is a considerable number of landfills with the potential to damage groundwater in many parts of the world. While the data on the exact magnitude of the challenge in China and India remain sketchy, it is clear that the US challenge is overwhelming, says Patrick Horner, Global Sales Manager for Zero-Liquid Discharge at Alfa Laval.