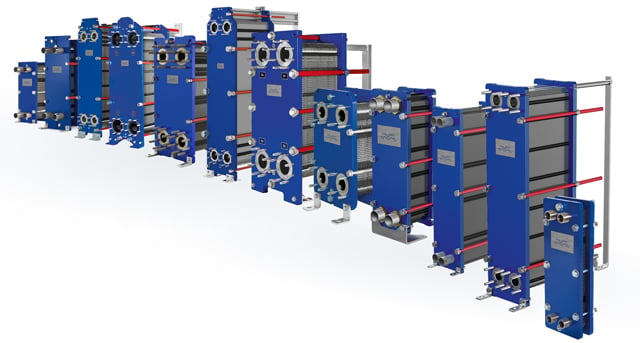

Gasketed plate-and-frame heat exchangers (GPHEs) provide efficient heat transfer in compact equipment with a small footprint - much smaller and more efficient than shell-and-tube heat exchangers.

Plate heat exchangers are designed to optimize heat transfer, because the corrugated plates provide by far the greatest surface area through which the heat can be drawn from one gas or liquid to the other.

The units also have a flexible design and are easy to service and maintain.

The product range is extremely wide and is used in duties for heating, cooling, heat recovery, evaporation and condensation in industries ranging from HVAC, refrigeration, engine cooling, dairy and food to heavier processes like chemical processing, oil production and power generation.

Learn more about GPHEs vs shell-and-tube heat exchangers

Gasketed plate heat exchangers may be the industry standard for general heating and cooling duties, but the technology inside a GPHE is far from standard. All plate heat exchangers are NOT created equal, and we've seen the consequences of choosing heat exchangers purely based on cost. We understand cost is important, but in most circumstances the costs to repair or replace units, as well as the inefficiencies of undersized units, far outweigh the upfront capital cost savings.

Gasketed plate heat exchangers may be the industry standard for general heating and cooling duties, but the technology inside a GPHE is far from standard. All plate heat exchangers are NOT created equal, and we've seen the consequences of choosing heat exchangers purely based on cost. We understand cost is important, but in most circumstances the costs to repair or replace units, as well as the inefficiencies of undersized units, far outweigh the upfront capital cost savings.

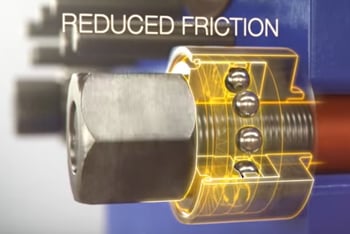

When choosing a gasketed plate heat exchanger, there are a number of plate and frame features you'll want to take into consideration.

Click here to view GPHE features that matter

Industrial - an extremely versatile range of heat exchangers for use in all types of industries

AlfaQ AHRI certified - similar to Industrial GPHEs, but are AHRI certified for HVAC applications

Industrial semi-welded - used in refrigeration when gaskets are not suitable for one of the media and when higher design pressures are needed

WideGap - used for applications involving fibrous liquids, highly viscous fluids, and fluids containing coarse particles

AlfaVap evaporators - tailor-made, rising film plate surface evaporator

AlfaCond condensers - a compact, plate surface vacuum condenser

Diabon - graphite heat exchanger used for tough corrosive media

Selecting the right GPHE can be a challenge, but we're here to help. We've created a simple selection guide to help guide you toward the best GPHE for your application. However, it's always best to eventually talk to one of our expert engineers so they can make sure you get the perfect fit.

Get in touch with a GPHE expert

Plate heat exchangers have an essential role in most applications. If they function poorly, they may lead to lower product quality, reduced safety and higher energy costs. And if they fail, they can lead to costly downtime and major losses in production. This makes it important to perform maintenance – and important to do it correctly.

Alfa Laval also offers a complete 360° Service Portfolio for gasketed plate heat exchangers.

Plate heat exchangers vs shell-and-tube

Download - The theory behind heat transfer