Webinar: How to move from preventive to predictive maintenance of your decanter centrifuge

View this webinar on demand

We all know what a headache an unplanned shutdown can be. From equipment repairs to late or unfilled orders, the costs could end up in the tens of thousands. What if there were a way to predict problems in your decanter centrifuge before they happened?

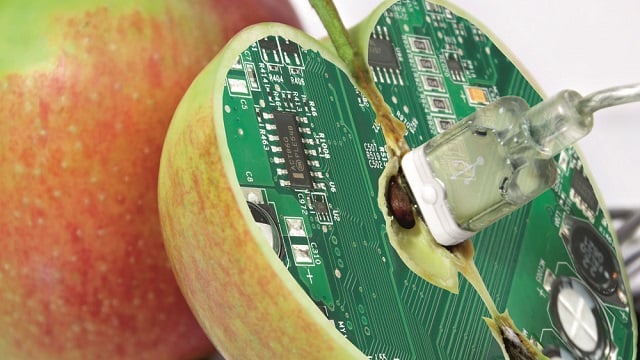

This short webinar introduces Alfa Laval’s condition monitoring system, ConditionAlert TM. This state-of-the-art technology monitors your decanter centrifuge 24/7 and identifies early-stage defects in the main bearings and conveyor bearings. You’ll receive an early warning of defects and a service recommendation well before problems arise so you can take action before a small issue turns into a major catastrophe.

What you’ll learn:

- Why predictive vs preventive maintenance?

- How can businesses use data to make better decisions?

- How to decide when it’s the right time for predictive maintenance

You may also be interested in:

Maximize operating reliability with Alfa Laval IoT Services

Alfa Laval’s IoT Services is a range of digital services that maximizes operating reliability and uptime in food & beverage processing plants.

Minimize operating cost with Alfa Laval IoT Services

Alfa Laval’s IoT Services is a range of digital services aiming to reduce operating costs and maximize operating reliability in wastewater plants. Our Connectivity Solutions taking advantages of Industrial Internet of Things (IIoTs) technologies help us serve you better in domains such as predictive preventive maintenance, remote control, optimisation and more.